Yeah, but could it be better? Maybe some hand blending, like porting a cylinder head?

The pattern control seems to be working, but maybe some of those wiggles would smooth out. 🤷🏻♂️

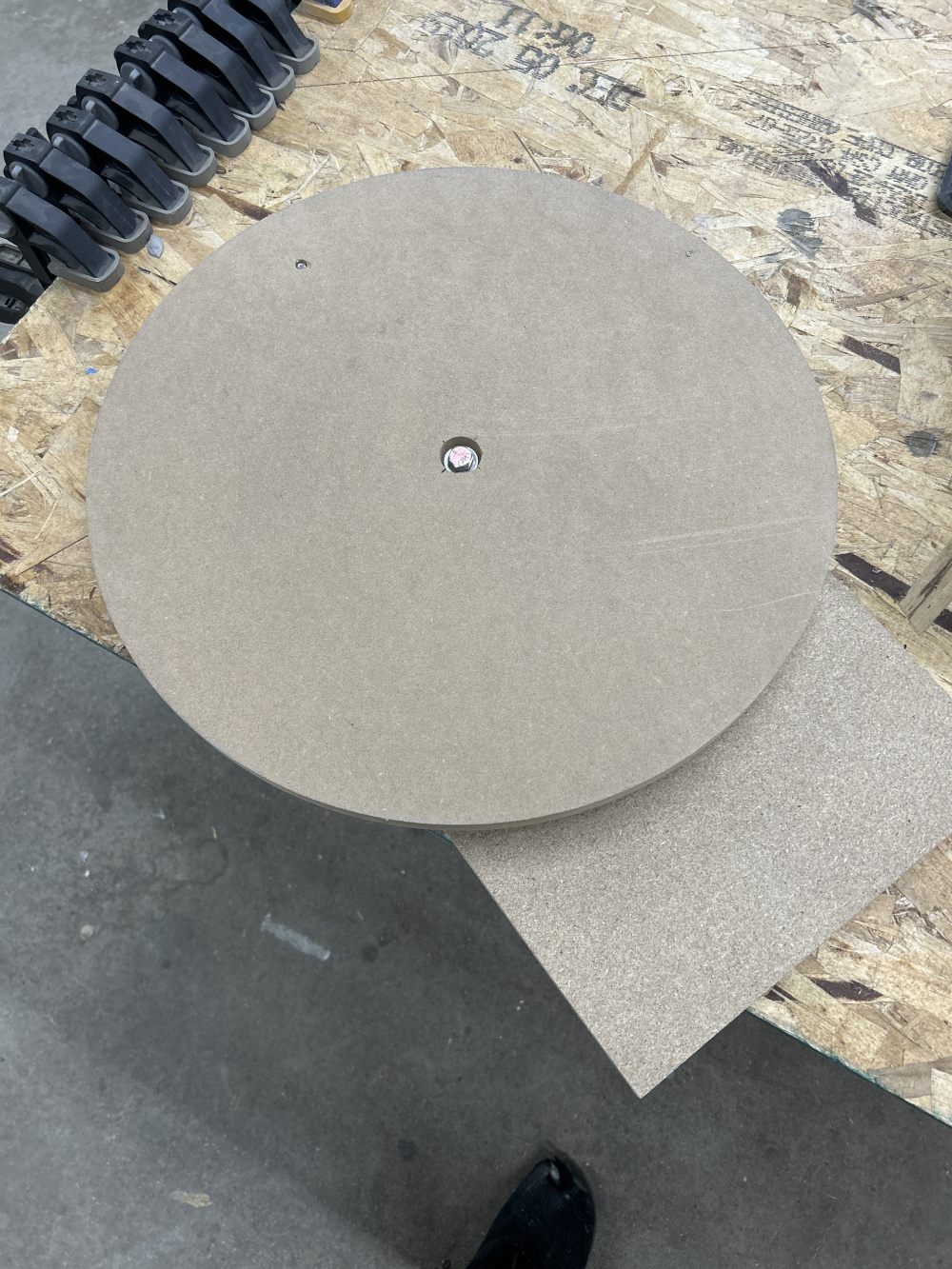

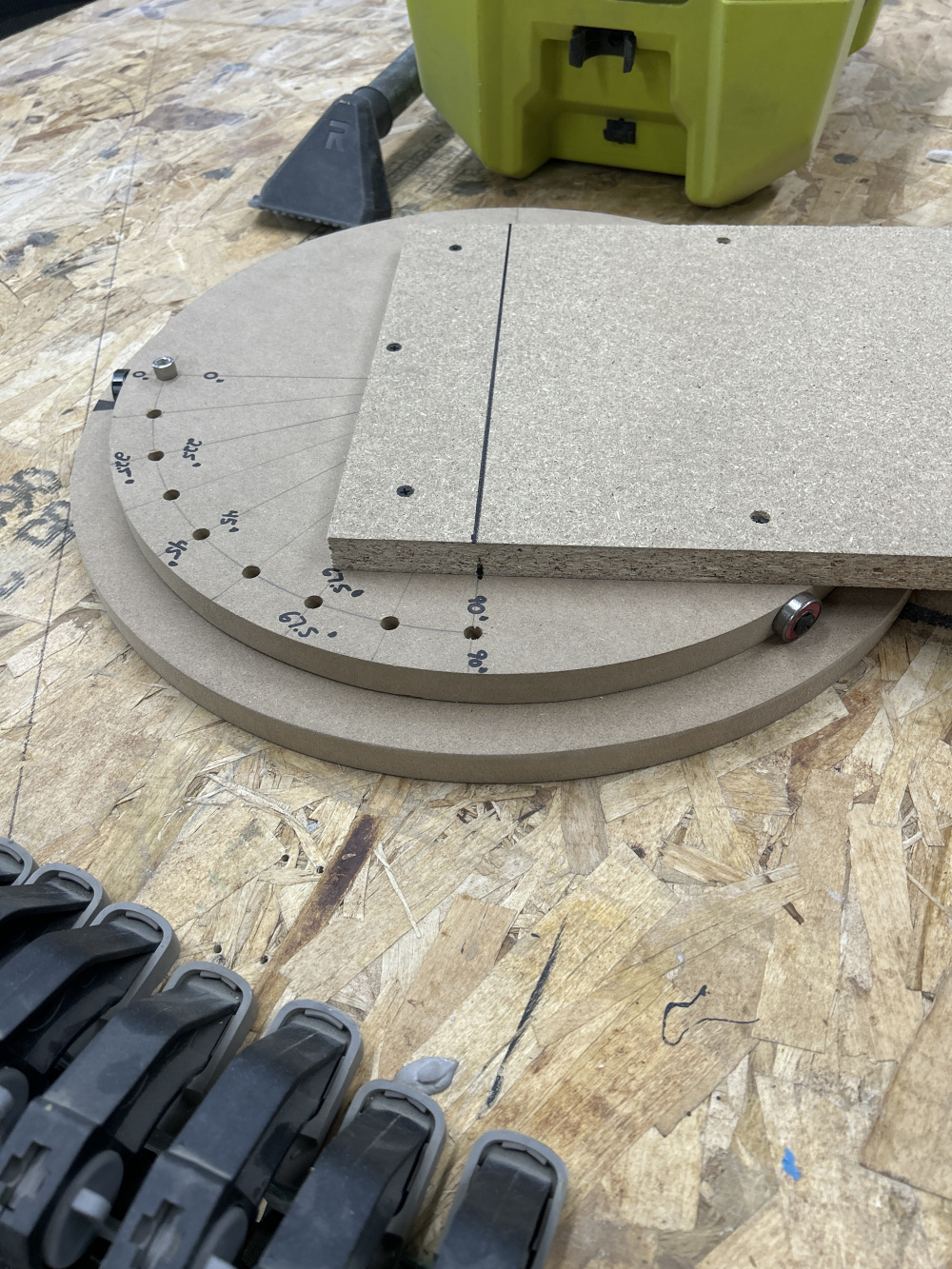

I seen Johnny mention it in a different thread. Here’s my cheap turntable for stand mount and floor stand speakers. Just two round pieces of wood and your average fidget spinner for the bearings and a quarter inch bolt with a couple washers through the center.

Thanks that pretty much answers any questions I had! For feet, more than 3 would be wobbly on anything but perfectly flat floor unless adjustable, but only 3 I could see being a stability issue.

I like this! I've had thoughts of a ball tipped router bit in a circle jig making a path, and then using a bag of marbles with a center pivot. Center bolt for spacing and such.

It's when they bunch-up and contact each other and you get some dust in there that the marbles/balls become annoying . . . this is why bearings have ball spacers and need lots of grease . . .

Probably still need an outboard caster or two on the backside on an extension to stabilize the structure Ken, especially if testing larger cabinets as the need to place the front edge of the cabinet right on the center of rotation makes the whole contraption back-heavy/unstable . . .

Comments

Yeah, but could it be better? Maybe some hand blending, like porting a cylinder head?

The pattern control seems to be working, but maybe some of those wiggles would smooth out. 🤷🏻♂️

Yep. Where going to run with it. Looks pretty good for crap setup I made. I’m having some aluminum mounting plates made for the Wavecor tweeters.

https://www.jfcomponents.com/

I seen Johnny mention it in a different thread. Here’s my cheap turntable for stand mount and floor stand speakers. Just two round pieces of wood and your average fidget spinner for the bearings and a quarter inch bolt with a couple washers through the center.

https://www.jfcomponents.com/

https://www.jfcomponents.com/

https://www.jfcomponents.com/

Sounds like I need to do something like this sooner than later. Got any pics of the bottom?

I should put some feet on it.

https://www.jfcomponents.com/

Sideview.

https://www.jfcomponents.com/

Thanks that pretty much answers any questions I had! For feet, more than 3 would be wobbly on anything but perfectly flat floor unless adjustable, but only 3 I could see being a stability issue.

Lazy Susan bearings are ideal for this application.

Ron

Nice, simple design! Thanks for the details. This gives me some ideas for building a new and improved turntable system.

I like this! I've had thoughts of a ball tipped router bit in a circle jig making a path, and then using a bag of marbles with a center pivot. Center bolt for spacing and such.

InDIYana Event Website

Wolf, I tried that. Do yourself a favor, don't. Ended up using bearings almost exactly like hifiside.

so, steelies vs glassies/ cat eyes… ha

It's when they bunch-up and contact each other and you get some dust in there that the marbles/balls become annoying . . . this is why bearings have ball spacers and need lots of grease . . .

Barstool swivel w/ ball bearings --> https://www.amazon.com/Replacement-,Square-Mechanism-Furniture-Bearing/dp/B08DRCFTRX/ref=asc_df_B07BJX6HD5?tag=bngsmtphsnus-20&linkCode=df0&hvadid=79920869053519&hvnetw=s&hvqmt=e&hvbmt=be&hvdev=c&hvlocint=&hvlocphy=&hvtargid=pla-4583520395958019&th=1

Depends on the marbles I suppose. Most of the "pretty" ones are not truly round nor identical size. I could see that being a show stopper on it's own.

How about this? $7 supports 500lb.

https://amazon.com/gp/product/B099J97CPP/ref=ewc_pr_img_3?smid=A3UH1NVWKYM3SI&th=1

Rockler sell several lazy Susan bearings as well.

Just saying….. cheap.

https://www.jfcomponents.com/

What keeps the bearing aligned perpendicular to the mounting circle without wallowing out in that soft MDF core-wood, HiFi?

I like the concept but loading a speaker or two on it looks like it will compress the wood and fail.

I 3d printed mounts for my bearings. Casters can be very cheap as well. Lazy Susan might be the best cost/performance option.

Probably still need an outboard caster or two on the backside on an extension to stabilize the structure Ken, especially if testing larger cabinets as the need to place the front edge of the cabinet right on the center of rotation makes the whole contraption back-heavy/unstable . . .

https://www.hobbylobby.com/Crafts-Hobbies/Wood-Crafts-Blank-Surfaces/Accessories-Hardware-Tools/Silver-Lazy-Susan-Hardware/p/81027111?gclid=EAIaIQobChMIjpTQ5ZzCgQMVuPHjBx1rSAmeEAQYAiABEgIVz_D_BwE

But but how do you assemble that .

https://www.jfcomponents.com/

^ that one is a choking hazard for small children for some reason . . .

Assembly requires access holes for screws to be drilled on one or the other mating platforms, HiFi.

You drill holes in the base to access the screw holes to attach the top.

http://wordsnwood.com/2018/lazysusan/

Just a small bushing from any hardware store. Most of the weight is on the center bolt and washers.

https://www.jfcomponents.com/

I'm late to the party but the FR graph looks good as it avoids the infamous 10K dip.

They’re not very matched. Well that sucks.

https://www.jfcomponents.com/

They look great to me!

Looks like they peeled off the substrate though - did you use that Elmer's spray adhesive on them?

Lol. No that’s for grill cloth

https://www.jfcomponents.com/