I have a WoodRiver Thumbnail roundover bit, a CMT 1" roundover, and a Freud Quadracut 0.75" roundover bit.

AND, I have the same Ryobi router pictured above. Don't be surprised if the router will need plunged under operation to remove some of the aluminum mounts inside the bottom orifice. This is because these bits are HUGE. No worries, the bits being brand new will shave it down without issue. Been there done that.

I knew a cabinet maker [Luke Johnson] in my youth who lost a kidney and almost bled to death while forming mouldings on a shaper table when one of the cutters broke-off and shot right through him.

Don't push these [large diameter] things with too much load - let them do the work in incremental steps.

I’ve got my 1 1/2” Yonico bit in a Grizzly router table with an old craftsman router that has adjustable speed. No real issues. I have used on plywood and made small cuts to keep tear out down. I never ran it faster than the lowest speed.

What John said. Slow RPM, it'll be fine.

I was looking at that bit, too. Then my buddy came through with a cutter for his shaper. I took that route to do the round overs on a desk I'm building for my wife.

Sorry to disagree but climb cutting could be disastrous with a bit that large. I agree with the multiple passes approach.

It depends upon the grain of the material and depth of cut but I don't see any disagreement - only misunderstanding.

Large diameter router bits should be handled in a stationary machine/table so that the lightest object with the lowest mass is being routed with a manageable bite [depth of cut] into the material so that it isn't flung from the operators grasp.

@Eggguy said:

Sorry to disagree but climb cutting could be disastrous with a bit that large. I agree with the multiple passes approach.

You appear to be correct.

Quote from the article: "A few words of warning: Although you can safely climb-cut with small-diameter bits at the router table, NEVER attempt a climb cut with a large one, such as a panel-raising bit. The surface of the profile is what matters, but a 1⁄2 " quarter-round bit is as large as you'd want to use."

Reconsider depth of the cut and multiple passes.

Again - it depends upon the grain of the material and depth of cut.

MDF - go for it.

Knotty material such as burl/tree crotch/lateral grain - go slow with small depth to avoid tear-out.

I say this being that it is easy to grab the workpiece doing this, causing damage to the workpiece, or maybe yourself. Not that it doesn't happen on occasion to everyone, as it does even to me, and even with the little trim routers. A GOOD GRIP on the router is something I do not take lightly, and has saved me a couple times now. It does not take much for this to occur, so I would say do not get overly comfortable or complacent with your power tools. Be careful and keep your fingers.

Those look pretty nice, Brad. I love ribbon tweeters and find it increasingly difficult to get excited about domes. I think another source for ribbons would be very welcome and count me in for a pair if you decide to offer these.

@jr@mac said:

Those look pretty nice, Brad. I love ribbon tweeters and find it increasingly difficult to get excited about domes. I think another source for ribbons would be very welcome and count me in for a pair if you decide to offer these.

A comment on your IEC test baffle thread, I'm posting here to keep that thread clean.

The phone-pics of the monitor are pretty poor resolution - some worse than others. I can see what needs to be seen on my monitor, but not if I'm looking on my phone. You may already know this, but using the "snipping" tool in Windows will produce much better results.

Press ctrl-s-windows at the same time to bring up the snipping tool.

Choose a particular rectangle or the whole screen to snip (with rectangle you can cut the top ribbon of Omnimic as well as the Windows task bar at the bottom of the monitor to just focus on the measurment results)

Add markup with the pen or pencil tool if desired - for example a circle or arrow in a high-contrast color point out a peak or resonance (see red arrow in 2nd image)

Click save (floppy disk icon) in top right corner (see green arrow in 2nd image)

Of course, if this is obvious or just not useful feel free to ignore it.

Comments

I was hoping on this router plate. It should work. I might need a variable speed controller though.

https://www.jfcomponents.com/

I’m going to chuck it up tomorrow and one of my routers and see if it vibrates too bad. If it does Amazon, can I have it back

https://www.jfcomponents.com/

I have a WoodRiver Thumbnail roundover bit, a CMT 1" roundover, and a Freud Quadracut 0.75" roundover bit.

AND, I have the same Ryobi router pictured above. Don't be surprised if the router will need plunged under operation to remove some of the aluminum mounts inside the bottom orifice. This is because these bits are HUGE. No worries, the bits being brand new will shave it down without issue. Been there done that.

Yes, larger than 1" RO should be table used.

Next step up is a shaper table.....

InDIYana Event Website

. . . AND, you should "climb cut" the work piece instead of trying to hog it all in one pass.

https://www.woodmagazine.com/tool-reviews/routers/climb-cutting-explained

I knew a cabinet maker [Luke Johnson] in my youth who lost a kidney and almost bled to death while forming mouldings on a shaper table when one of the cutters broke-off and shot right through him.

Don't push these [large diameter] things with too much load - let them do the work in incremental steps.

I’ve got my 1 1/2” Yonico bit in a Grizzly router table with an old craftsman router that has adjustable speed. No real issues. I have used on plywood and made small cuts to keep tear out down. I never ran it faster than the lowest speed.

What John said. Slow RPM, it'll be fine.

I was looking at that bit, too. Then my buddy came through with a cutter for his shaper. I took that route to do the round overs on a desk I'm building for my wife.

Sorry to disagree but climb cutting could be disastrous with a bit that large. I agree with the multiple passes approach.

I do multiple passes with all big bits. My last 3/4” round over Orange tool lasted almost 12 years.

https://www.jfcomponents.com/

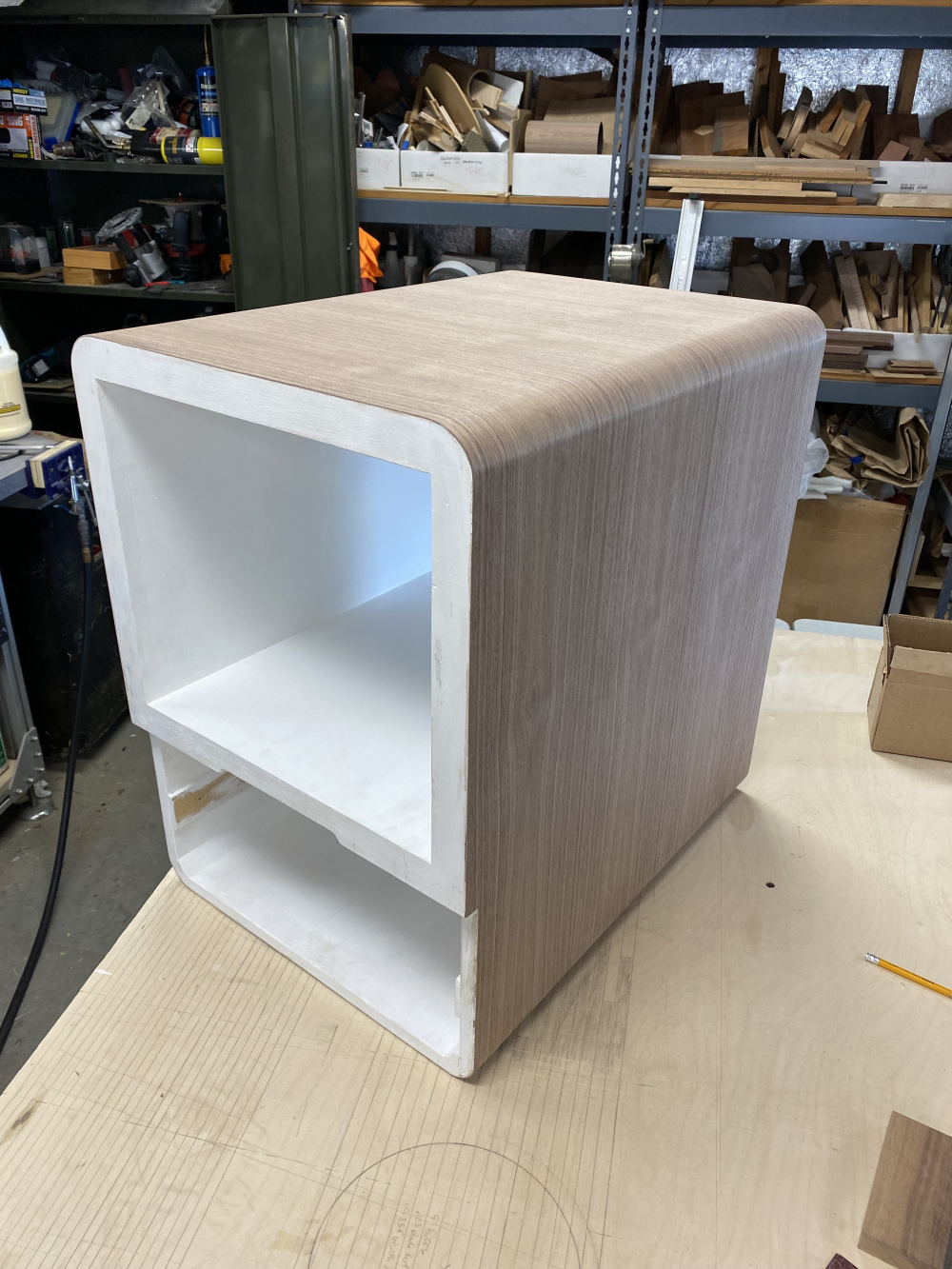

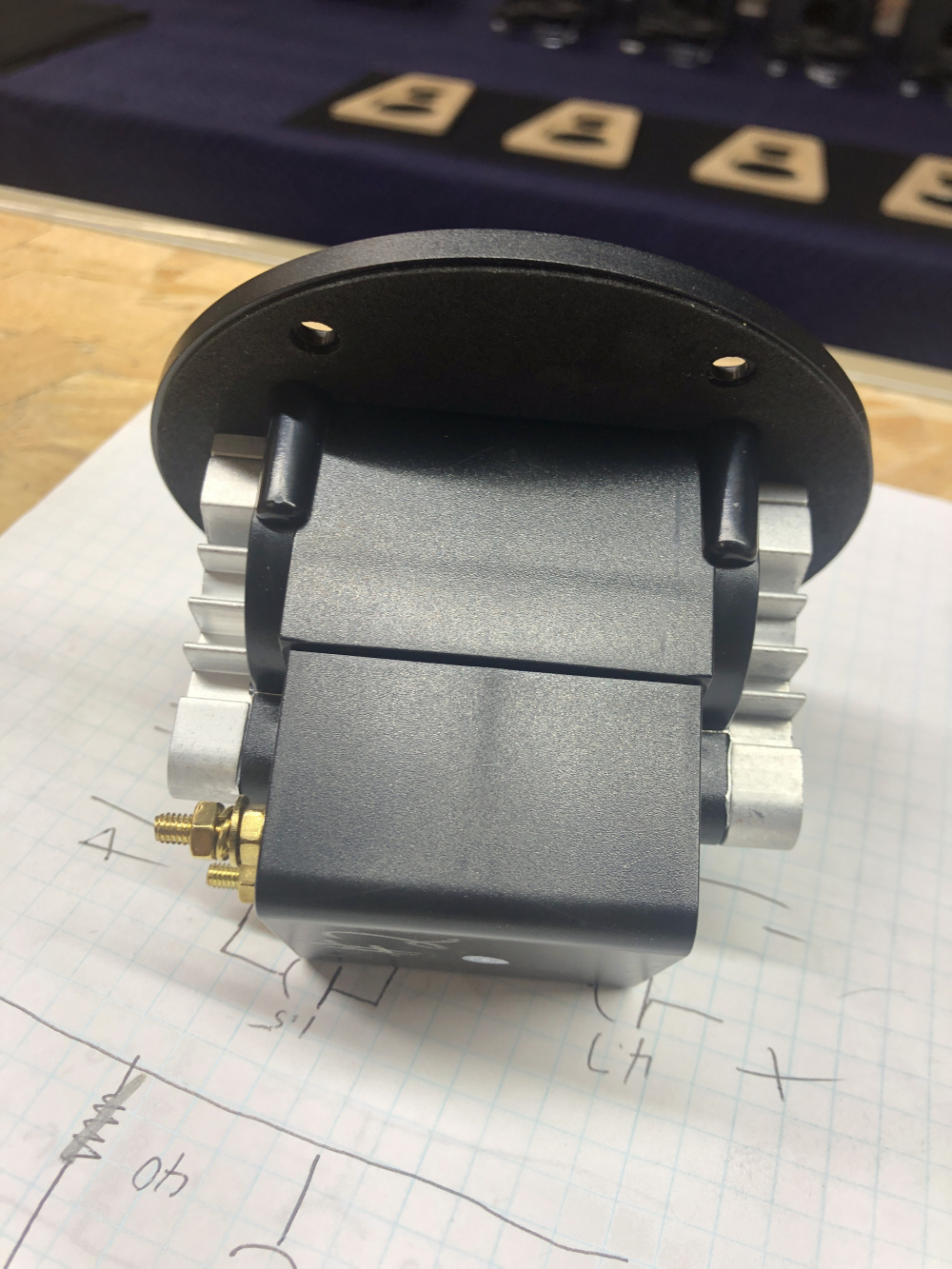

Machinist showed today with a small run of some parts. Finished and unfinished.

https://www.jfcomponents.com/

.> @Eggguy said:

It depends upon the grain of the material and depth of cut but I don't see any disagreement - only misunderstanding.

Large diameter router bits should be handled in a stationary machine/table so that the lightest object with the lowest mass is being routed with a manageable bite [depth of cut] into the material so that it isn't flung from the operators grasp.

You appear to be correct.

Quote from the article: "A few words of warning: Although you can safely climb-cut with small-diameter bits at the router table, NEVER attempt a climb cut with a large one, such as a panel-raising bit. The surface of the profile is what matters, but a 1⁄2 " quarter-round bit is as large as you'd want to use."

Reconsider depth of the cut and multiple passes.

Again - it depends upon the grain of the material and depth of cut.

MDF - go for it.

Knotty material such as burl/tree crotch/lateral grain - go slow with small depth to avoid tear-out.

Experience will settle the matter.

Try both and see for yourselves.

Be safe.

I try not to climb cut at all, as it is not a safe operation method.

InDIYana Event Website

Fair enough. I shall stand corrected.

I say this being that it is easy to grab the workpiece doing this, causing damage to the workpiece, or maybe yourself. Not that it doesn't happen on occasion to everyone, as it does even to me, and even with the little trim routers. A GOOD GRIP on the router is something I do not take lightly, and has saved me a couple times now. It does not take much for this to occur, so I would say do not get overly comfortable or complacent with your power tools. Be careful and keep your fingers.

InDIYana Event Website

No.no. The shit a find laying around here.

https://www.jfcomponents.com/

Hivi? Nope. GRS? Nope. Could be JF?

https://www.jfcomponents.com/

Very interested...

Now we're talking

If you source an egg shaped concentric driver I guarantee you will sell at least two

Those look pretty nice, Brad. I love ribbon tweeters and find it increasingly difficult to get excited about domes. I think another source for ribbons would be very welcome and count me in for a pair if you decide to offer these.

Price range?

Me too!

Interested in these ribbons if you getting them soonish

Ditto

I'd like to see some tech specs/FR sweeps/distortion plots yet but would also be interested in a pair . . . and some CEOS-6 (hint).

Looks very similar to the GRS RT1.R-8 to me.

There all based off this

https://www.madisoundspeakerstore.com/ribbon-tweeters/fountek-neocd3.0m-blk-3-ribbon-tweeter-round-flange-black/

https://www.jfcomponents.com/

You aren’t far off, a million years ago, these were made and sounded fantastic.

https://http2.mlstatic.com/D_NQ_NP_3719-MLA4857637407_082013-O.webp

Anyway sorry for the hihack Brad! Back to your regularly scheduled thread.

Brad,

A comment on your IEC test baffle thread, I'm posting here to keep that thread clean.

The phone-pics of the monitor are pretty poor resolution - some worse than others. I can see what needs to be seen on my monitor, but not if I'm looking on my phone. You may already know this, but using the "snipping" tool in Windows will produce much better results.

Of course, if this is obvious or just not useful feel free to ignore it.