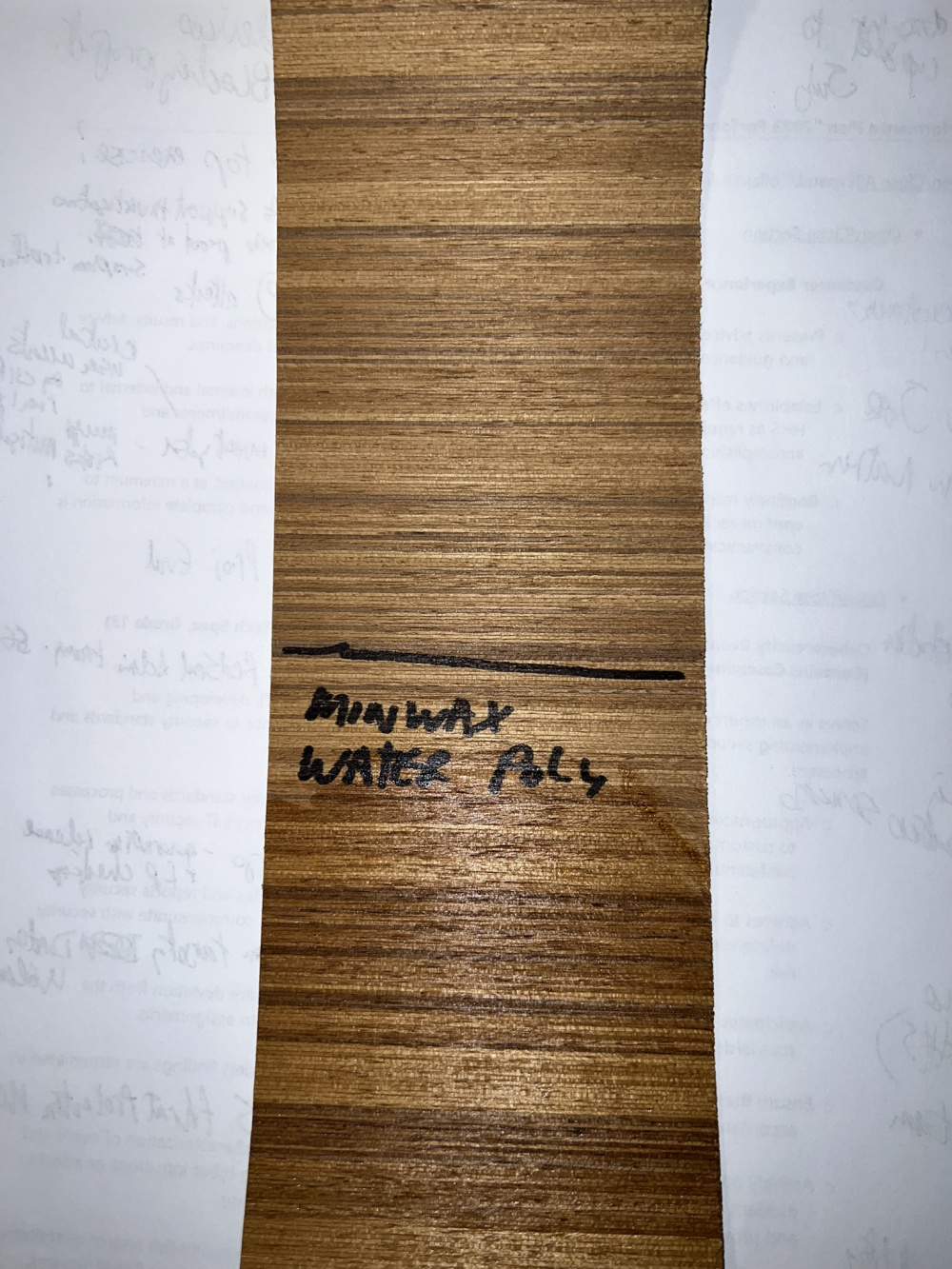

I'd used teak on a build a few years ago, and decided then that the contrast was the fun part, and I should try to not darken the light bands too much. This is with water based poly. I think it looks good enough.

But Chahly - Stahkist don't want speakers that look good, Stahkist wants speakers that sound good!

Have you tried the 1/3 Boiled Linseed Oil, 1/3 oil based ply, 1/3 mineral spirits recipe? I believe DaveFred posted it a long time ago and PwrRyd has used it several times. Every veneer I have tried it on, it looks absolutely great. The plain water-based poly looks good, so not sure you need to experiment, but just want to put it out there as a possibility.

Water based poly is probably the best for not darkening the lighter stuff.

Next project though I think I'm going to try the Bulls Eye SealCoat since it is actually just light color dewaxed shellac. I'm not a fan of linseed/ oil based poly since it oxidizes amber/orange over time and you realy have no control over that.

Got the first coat of water poly on, but got some bubbles even though I bought a special nice bristle brush., so will need a second coat. Any advice how NOT to get bubbles brushing on poly?

But Chahly - Stahkist don't want speakers that look good, Stahkist wants speakers that sound good!

I'd like to try Osmo or Rubio Monocoat, but I need a low-voc finish since I've got the garage door closed for winter. Are any of these one-coat wipe-on finishes low-voc?

But Chahly - Stahkist don't want speakers that look good, Stahkist wants speakers that sound good!

I'd like to try Osmo or Rubio Monocoat, but I need a low-voc finish since I've got the garage door closed for winter. Are any of these one-coat wipe-on finishes low-voc?

I'd like to try Osmo or Rubio Monocoat, but I need a low-voc finish since I've got the garage door closed for winter. Are any of these one-coat wipe-on finishes low-voc?

You’re welcome. I really like the stuff although it’s expensive. A little goes a long way. I used the maintenance oil on the top to give it a little sheen versus the flat matte look. They also have a new sheen plus that is 0% VOC.

I don't recall fumes with Osmo, site shown pretty low VOCs. For poly I prefer to use a paint pad with very thin coats, always brushing in one direction.

I got it for $100 in 2017 so $120 is a steal nowadays.

I've had no luck brushing water based poly. It dries way too quickly to lay flat and let bubbles pop. Spray is the way to go. Worth building a little take-down spray booth in the garage IMO. And normally I'd be the last person to suggest such things (too frugal). The results have me convinced. It is quite the game changer for water based poly IMO. Cleanup is super easy too. 5min max if you have good water pressure.

I got it for $100 in 2017 so $120 is a steal nowadays.

I've had no luck brushing water based poly. It dries way too quickly to lay flat and let bubbles pop. Spray is the way to go. Worth building a little take-down spray booth in the garage IMO. And normally I'd be the last person to suggest such things (too frugal). The results have me convinced. It is quite the game changer for water based poly IMO. Cleanup is super easy too. 5min max if you have good water pressure.

Thanks buddy - I've got something like that in storage - I'll give it a try with the water poly.

But Chahly - Stahkist don't want speakers that look good, Stahkist wants speakers that sound good!

I don't know how well my technique would work with water based poly. I use Minwax wipe on poly applied with a foam brush. I quickly coat the side of the cabinet and as soon as I'm done I make passes over the finish going from one end to other in one pass. I move over the width of the brush and make another pass and repeat until I've covered the entire side. There are bubbles when I apply the first coat but making a second pass makes them disappear.

@Ron_E said:

I don't know how well my technique would work with water based poly. I use Minwax wipe on poly applied with a foam brush. I quickly coat the side of the cabinet and as soon as I'm done I make passes over the finish going from one end to other in one pass. I move over the width of the brush and make another pass and repeat until I've covered the entire side. There are bubbles when I apply the first coat but making a second pass makes them disappear.

Ron

Thanks Ron - I used to do a lot of wipe-on poly with foam brushes and results were ok.

But I think the wipe-on was oil based - for this teak I wanted water based poly.

So far, John H's advise seems to working fine. After a little scuff sanding with 220, the second

coat is going on much smoother. A close look after Iaid down the coat shows a lot of tiny bubbles,

but I think they burst before the surface sets up. Feels and looks good anyways.

But Chahly - Stahkist don't want speakers that look good, Stahkist wants speakers that sound good!

@DrewsBrews said:

Water based poly is probably the best for not darkening the lighter stuff.

Next project though I think I'm going to try the Bulls Eye SealCoat since it is actually just light color dewaxed shellac. I'm not a fan of linseed/ oil based poly since it oxidizes amber/orange over time and you realy have no control over that.

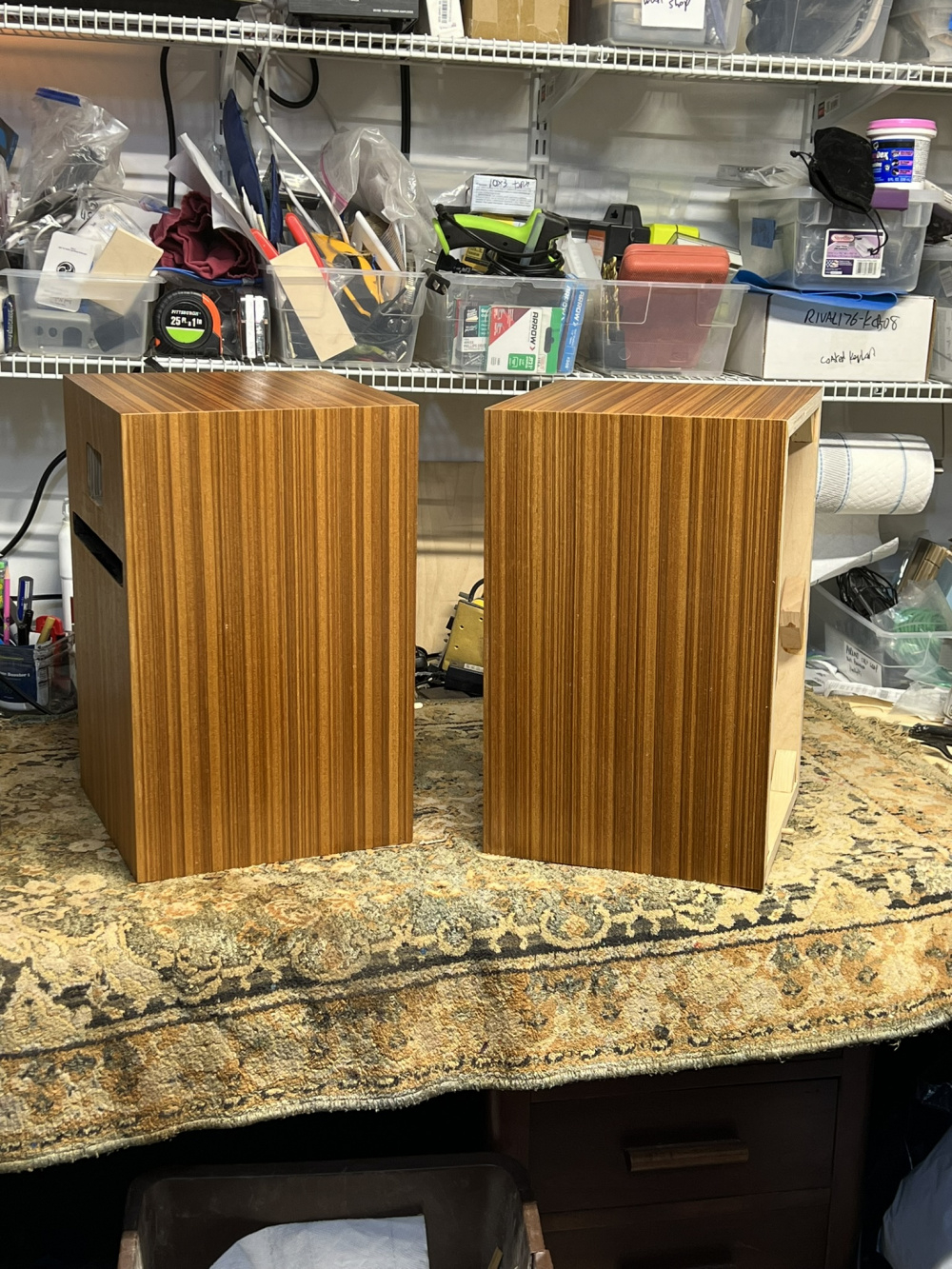

The first time I used teak veneer, I tried many different finishes, and the oil based finishes tended to darken the light stripes (same with zebrawood veneer) - so I knew that I wanted to use water based finish or lacquer for this. After 2 coats, the box is done. Now to trim the baffle and get to crossover work.

But Chahly - Stahkist don't want speakers that look good, Stahkist wants speakers that sound good!

Girlfriend says absolutely no sawdust in house, so I made up a table on sawhorses outside and trimmed the baffles.

Cold outside but worked pretty good.

This a baffle with a test of some DNA. I'm pretty sure this is the look I want.

But Chahly - Stahkist don't want speakers that look good, Stahkist wants speakers that sound good!

I was really frustrated by the slow pace of working a few hours at Make, and am much happier working at home as much as I can. Baffles are just about ready to receive the drivers. I found that I liked rattle-can spar urethane the best.

Used my trusty Bosch 1617 router to put a 1/2 inch chamfer all the way around the face.

But Chahly - Stahkist don't want speakers that look good, Stahkist wants speakers that sound good!

If they seem light now now, being oil based, in a year or two it will likely oxidize and darken to match pretty well.

Gosh, looking back I forgot you glued up these baffles yourself. Nice! That chamfer realy accents the solid wood effect of laminated boards well! I may need to use that idea in the future.

I need a 1/2" shank router table. I could realy do some damage with that. Figuratively, hopefully not (but probably) literally.

@DrewsBrews said:

If they seem light now now, being oil based, in a year or two it will likely oxidize and darken to match pretty well.

Gosh, looking back I forgot you glued up these baffles yourself. Nice! That chamfer realy accents the solid wood effect of laminated boards well! I may need to use that idea in the future.

I need a 1/2" shank router table. I could realy do some damage with that. Figuratively, hopefully not (but probably) literally.

Thanks for the kind words!

Yeah, totally glad I chose a chamfer versus a round over.

I started my woodworking journey with a cheap-ass Ryobi 1/4 inch collet router.

Even with that, I had the feeling that sometime the bit would deflect a little.

Very happy to use 1/2 inch shank bits whenever I can.

My "star" is a 1 1/2 inch long flush trim bit with double bearings. Makes baffle trimming much less troublesome, because it does not leave any marks on the veneer. https://a.co/d/2FEN0eS

But Chahly - Stahkist don't want speakers that look good, Stahkist wants speakers that sound good!

@rjj45 said:

My "star" is a 1 1/2 inch long flush trim bit with double bearings. Makes baffle trimming much less troublesome, because it does not leave any marks on the veneer.

Thanks, I just added that to my cart. I have a similar CMT bit from Menards but with only a single bearing.

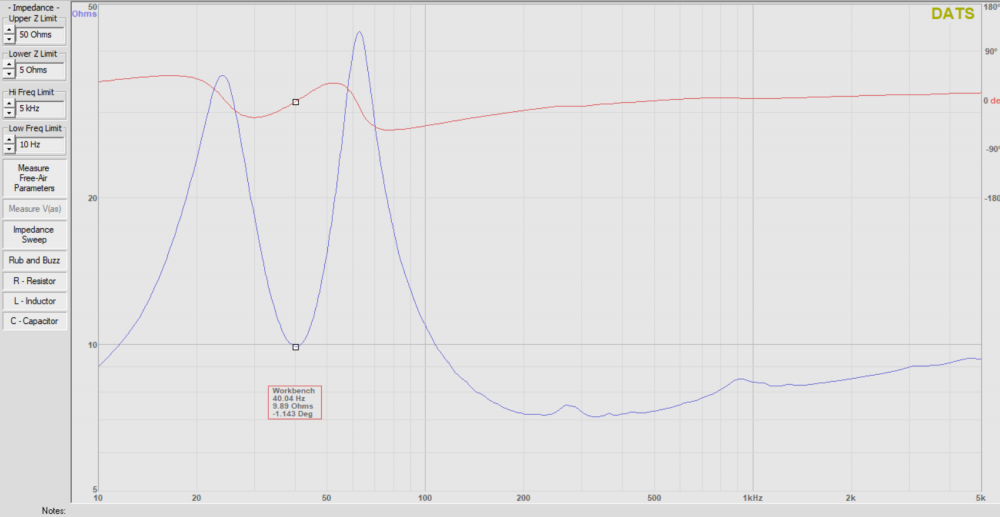

I am focusing more these days more aspects of speaker design, like verifying box tuning.

Here is a DATS sweep of the box as built.

Fb appears to be right at 40Hz, which is where I wanted it - WinISD model showed about 38Hz Fb, but I don't care about 2 Hz. A slightly more concerning aspect is the bumps in the impedance. Probably resonances in the TL plenum. Hornresp shows I can smooth them down with more stuffing. We shall see once I've measured FR.

But Chahly - Stahkist don't want speakers that look good, Stahkist wants speakers that sound good!

Hmm, one of Scott Hinsons criticisms for TLs is that the terminus "leaks" a lot of midrange. I never paid much attention to this even though Hornresp shows port output way into the midrange.

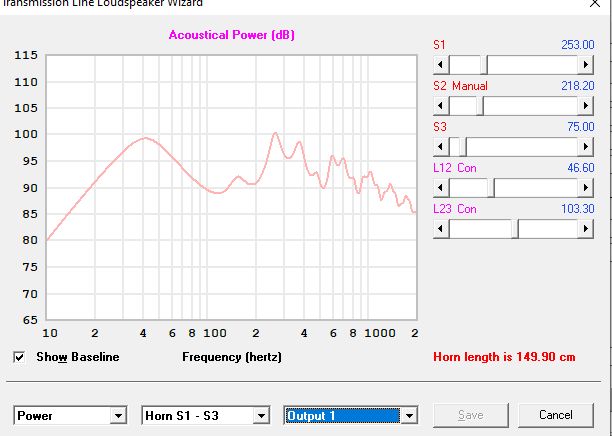

This is the Hornresp sim:

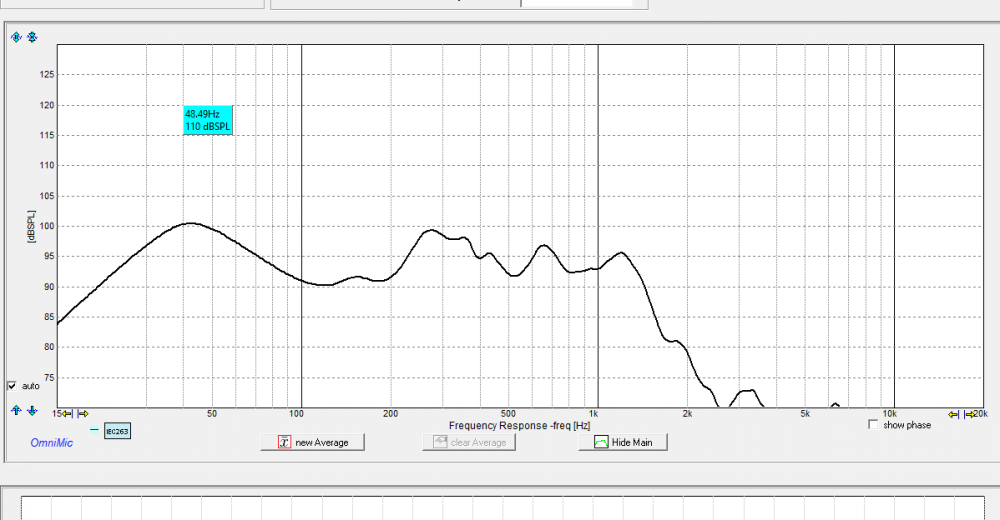

And here is the near miked port in the box as built:

Oh well, the box is all put together, so I can't fix this, but next build I will know....

But Chahly - Stahkist don't want speakers that look good, Stahkist wants speakers that sound good!

Continuing in my exploration of terminus "mid" leakage.

The total line length is about 150cm, and that should be about 250Hz,

which is where the first "bump" in port output occurs.

I first tried some pyramid acoustic foam I had in stock at the origin.

Pretty much no change in a terminus measurement.

I tried a little open cell foam in the exit, and as expected, pretty much killed the bass.

So then tried a bunch of Dow703 compressed fiberglass at the origin

Interesting - it affected Fb magnitude, but it also shifted Fb a little lower.

Comparing the absolute magnitude at Fb versus the leakage bumps,

The bumps at 250 and 500 are a little diminished (2-3 dB)

Looks like that is the best I can do at this time, since the box is glued up.

I've got several more TL experiments planned once I finish these.

But Chahly - Stahkist don't want speakers that look good, Stahkist wants speakers that sound good!

Comments

I'd used teak on a build a few years ago, and decided then that the contrast was the fun part, and I should try to not darken the light bands too much. This is with water based poly. I think it looks good enough.

Have you tried the 1/3 Boiled Linseed Oil, 1/3 oil based ply, 1/3 mineral spirits recipe? I believe DaveFred posted it a long time ago and PwrRyd has used it several times. Every veneer I have tried it on, it looks absolutely great. The plain water-based poly looks good, so not sure you need to experiment, but just want to put it out there as a possibility.

I like buffing on Osmo. Easy to apply and really shows the grain and color of the wood.

John your table looked outstanding with that finish. Which Osmo product was that?

Water based poly is probably the best for not darkening the lighter stuff.

Next project though I think I'm going to try the Bulls Eye SealCoat since it is actually just light color dewaxed shellac. I'm not a fan of linseed/ oil based poly since it oxidizes amber/orange over time and you realy have no control over that.

Osmo Polyx-Oil, 3011 Clear Gloss.

That stuff looks great! Might have to check it out.

Got the first coat of water poly on, but got some bubbles even though I bought a special nice bristle brush., so will need a second coat. Any advice how NOT to get bubbles brushing on poly?

I'd like to try Osmo or Rubio Monocoat, but I need a low-voc finish since I've got the garage door closed for winter. Are any of these one-coat wipe-on finishes low-voc?

Rubio is 0% VOC. Strong linseed oil smell which I kinda like but my wife hates.

https://www.rubiomonocoatusa.com/pages/0-voc

thanks, I didn't know that.

You’re welcome. I really like the stuff although it’s expensive. A little goes a long way. I used the maintenance oil on the top to give it a little sheen versus the flat matte look. They also have a new sheen plus that is 0% VOC.

I don't recall fumes with Osmo, site shown pretty low VOCs. For poly I prefer to use a paint pad with very thin coats, always brushing in one direction.

Thanks John - I'll try a paint pad.

Late to the party but PL Premium is an expanding glue and would've sealed that gap.

https://amazon.com/Wagner-Spraytech-0518080-Control-Multicolor/dp/B003PGQI48?th=1

I got it for $100 in 2017 so $120 is a steal nowadays.

I've had no luck brushing water based poly. It dries way too quickly to lay flat and let bubbles pop. Spray is the way to go. Worth building a little take-down spray booth in the garage IMO. And normally I'd be the last person to suggest such things (too frugal). The results have me convinced. It is quite the game changer for water based poly IMO. Cleanup is super easy too. 5min max if you have good water pressure.

Thanks buddy - I've got something like that in storage - I'll give it a try with the water poly.

I don't know how well my technique would work with water based poly. I use Minwax wipe on poly applied with a foam brush. I quickly coat the side of the cabinet and as soon as I'm done I make passes over the finish going from one end to other in one pass. I move over the width of the brush and make another pass and repeat until I've covered the entire side. There are bubbles when I apply the first coat but making a second pass makes them disappear.

Ron

Thanks Ron - I used to do a lot of wipe-on poly with foam brushes and results were ok.

But I think the wipe-on was oil based - for this teak I wanted water based poly.

So far, John H's advise seems to working fine. After a little scuff sanding with 220, the second

coat is going on much smoother. A close look after Iaid down the coat shows a lot of tiny bubbles,

but I think they burst before the surface sets up. Feels and looks good anyways.

The first time I used teak veneer, I tried many different finishes, and the oil based finishes tended to darken the light stripes (same with zebrawood veneer) - so I knew that I wanted to use water based finish or lacquer for this. After 2 coats, the box is done. Now to trim the baffle and get to crossover work.

These are going to look good! Hope they sound good also....

Think I will use oil based finish on the birch, to warm it up a bit.

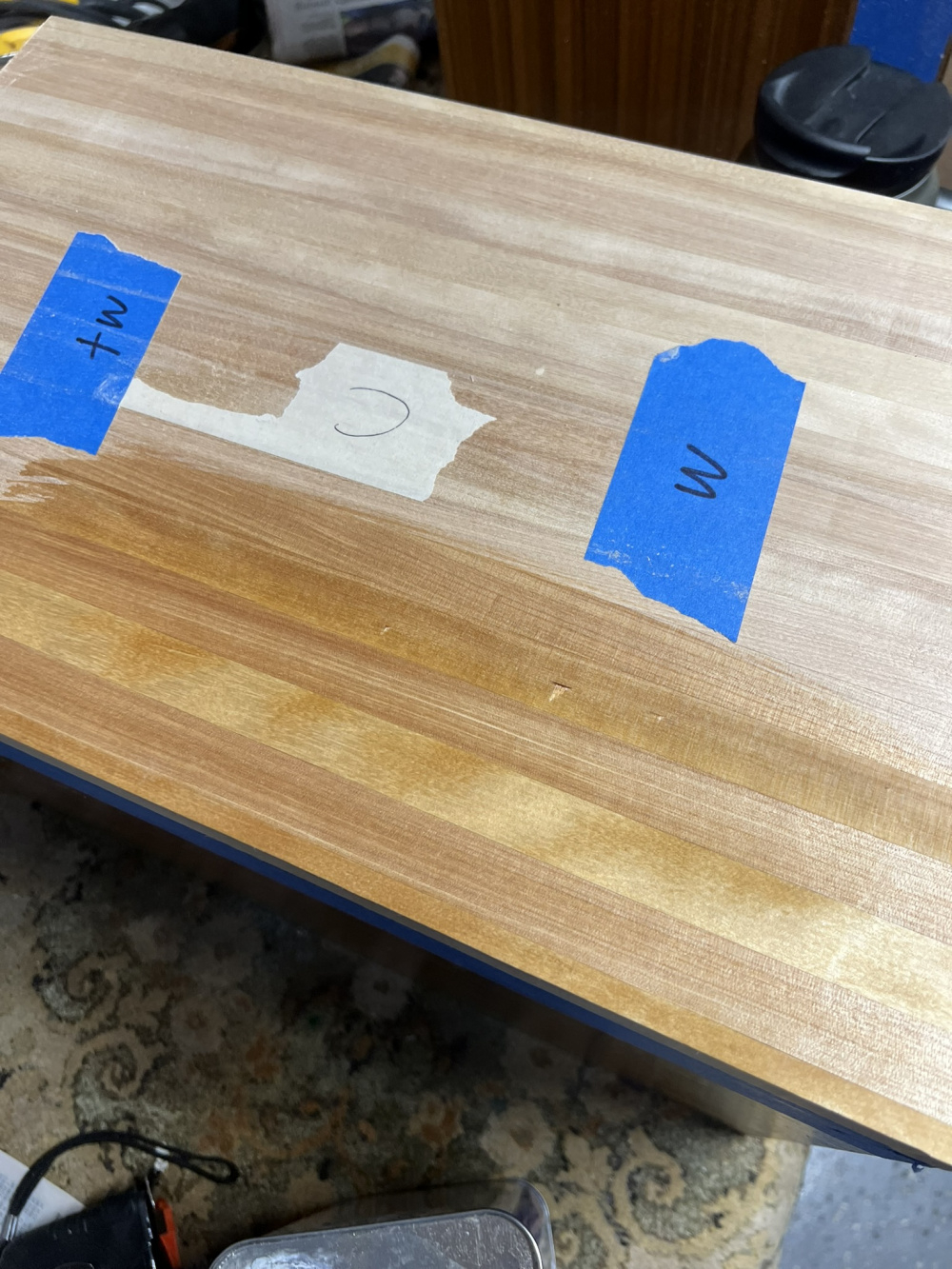

Girlfriend says absolutely no sawdust in house, so I made up a table on sawhorses outside and trimmed the baffles.

Cold outside but worked pretty good.

This a baffle with a test of some DNA. I'm pretty sure this is the look I want.

I was really frustrated by the slow pace of working a few hours at Make, and am much happier working at home as much as I can. Baffles are just about ready to receive the drivers. I found that I liked rattle-can spar urethane the best.

Used my trusty Bosch 1617 router to put a 1/2 inch chamfer all the way around the face.

If they seem light now now, being oil based, in a year or two it will likely oxidize and darken to match pretty well.

Gosh, looking back I forgot you glued up these baffles yourself. Nice! That chamfer realy accents the solid wood effect of laminated boards well! I may need to use that idea in the future.

I need a 1/2" shank router table. I could realy do some damage with that. Figuratively, hopefully not (but probably) literally.

Thanks for the kind words!

Yeah, totally glad I chose a chamfer versus a round over.

I started my woodworking journey with a cheap-ass Ryobi 1/4 inch collet router.

Even with that, I had the feeling that sometime the bit would deflect a little.

Very happy to use 1/2 inch shank bits whenever I can.

My "star" is a 1 1/2 inch long flush trim bit with double bearings. Makes baffle trimming much less troublesome, because it does not leave any marks on the veneer.

https://a.co/d/2FEN0eS

Thanks, I just added that to my cart. I have a similar CMT bit from Menards but with only a single bearing.

Ready to start crossover work!

I am focusing more these days more aspects of speaker design, like verifying box tuning.

Here is a DATS sweep of the box as built.

Fb appears to be right at 40Hz, which is where I wanted it - WinISD model showed about 38Hz Fb, but I don't care about 2 Hz. A slightly more concerning aspect is the bumps in the impedance. Probably resonances in the TL plenum. Hornresp shows I can smooth them down with more stuffing. We shall see once I've measured FR.

Hmm, one of Scott Hinsons criticisms for TLs is that the terminus "leaks" a lot of midrange. I never paid much attention to this even though Hornresp shows port output way into the midrange.

This is the Hornresp sim:

And here is the near miked port in the box as built:

Oh well, the box is all put together, so I can't fix this, but next build I will know....

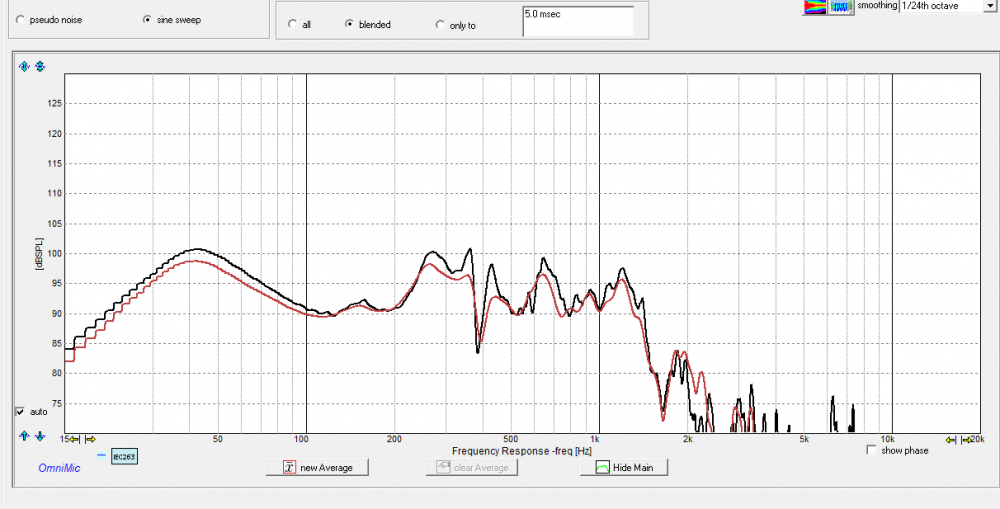

Continuing in my exploration of terminus "mid" leakage.

The total line length is about 150cm, and that should be about 250Hz,

which is where the first "bump" in port output occurs.

I first tried some pyramid acoustic foam I had in stock at the origin.

Pretty much no change in a terminus measurement.

I tried a little open cell foam in the exit, and as expected, pretty much killed the bass.

So then tried a bunch of Dow703 compressed fiberglass at the origin

Interesting - it affected Fb magnitude, but it also shifted Fb a little lower.

Comparing the absolute magnitude at Fb versus the leakage bumps,

The bumps at 250 and 500 are a little diminished (2-3 dB)

Looks like that is the best I can do at this time, since the box is glued up.

I've got several more TL experiments planned once I finish these.