Any LPG tank valve experts here?

My grill tank just hit empty and a newly refilled tank will not produced gas.

Another new tank does produce gas.

The failed one doesn't seem able to open the spring seal on the threaded connector - must be some internal fault?

I fired Blue Rhino/Amerigas via the State inspectors from my property last year and this little tank is from a local LPG company - Probably need to return it to the place I bought from for a replacement.

I suspect you are saying that the tank is faulty without saying it.

OK, got it working just now - it was stored in the garage and it was 97* here today and probably about 130* in the garage where it was stored - got shaken in transit to the grill on the porch - over pressured - locked-out internally.

Had to release the overload by unscrewing the regulator hose connection until it blew off briefly then reconnect to grill.

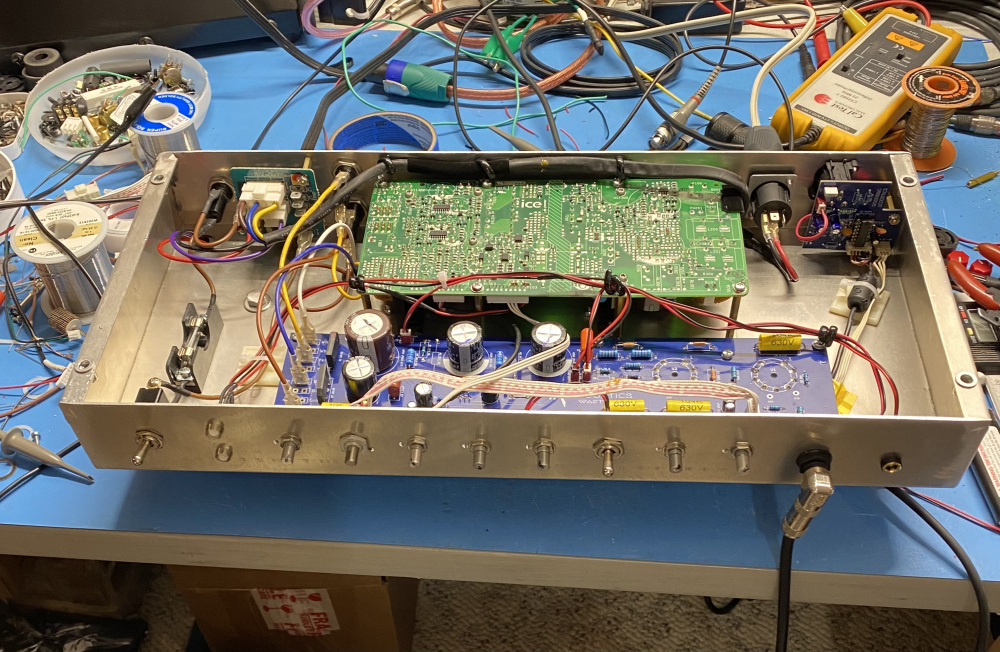

First one assembled. This was kind of a test to see if I had all the parts and pieces gathered up. It worked as designed👍🏻 Still working on the rear sticker, that's the last piece of the puzzle.

Stopped by the Walmart 3 miles from my house with the wife and kids...

Antron Brown and his top fuel dragster. Three time Top Fuel World Champion! He's on his way to Brainerd MN for this coming weekend's race there. He stopped here to support a local fireman's charity (not a sponsor that I know of). What a super cool guy. We all chit chatted for about 40 minutes about racing, life on the road, starting his own team, his kids, our kids, God, you name it. Love seeing guys like him who are so down to earth and not full of themselves. Will be cheering for him this weekend.

So our ticking time bomb (silver maple) in the front yard has developed a bug issue where we lost a limb 10 years ago. Anyone know what this insect is?

Did a search, and likely confirmed my suspicions. My guess is the green wasp is attracted to the critters eating the tree to get a good meal. Cuckoo wasps came up in the search, but uncertain they are what you actually see there.

@Nicholas_23 said:

So Toyota is into drag racing ? If so when did this happen? Did miss something ?

Just like in NASCAR... They don't and have never produced a front engine V8 car that is a two door sedan and rear wheel drive. But if you throw enough money at the sactioning body anything goes. I don't throw any shade towards Antron (AB Racing). If Toyolet is paying the racing bills... there is nothing produced by Toyota on that racing machine.

@Wolf said:

Did a search, and likely confirmed my suspicions. My guess is the green wasp is attracted to the critters eating the tree to get a good meal. Cuckoo wasps came up in the search, but uncertain they are what you actually see there.

Thanks Ben. I plan on having this tree removed as soon as the local tree companies slow down. They are all still slammed from the last round of storms and quoted prices would be extremely high.

Don't know why I have this fascination with bugs, but I find some of them interesting to watch or find. If I see a bug and I don't know what it is, I can snap an image on the phone and google will find it.

I went out to dinner last weekend and walked past the salon that cuts my hair. They were in the process of doing some cleaning and wanted to know if wanted some speakers that they had pulled from the rafters. I said sure and picked up a pair off extremely dusty Bose Model 101 Music Monitors. They look like they have single 3 1/2" paper cone driver in a cast resin box. They have some weight to them.

They don't measure very well. The vocal range is not bad but there's no bass and the highs pale in comparison to my Raal's. ;-) The price was right and I'll have to compare them to some of my small two ways some time.

Most people know what a 'Spitfire' aircraft is and would probably love to have one, this guy built one!

He used some different construction materials and techniques to the original and installed an Alison V12 instead of a Merlin, so you could argue it's not 'really' a Spitfire, but it looks great and was relatively affordable.

@Ron_E said:

I went out to dinner last weekend and walked past the salon that cuts my hair. They were in the process of doing some cleaning and wanted to know if wanted some speakers that they had pulled from the rafters. I said sure and picked up a pair off extremely dusty Bose Model 101 Music Monitors. They look like they have single 3 1/2" paper cone driver in a cast resin box. They have some weight to them.

They don't measure very well. The vocal range is not bad but there's no bass and the highs pale in comparison to my Raal's. ;-) The price was right and I'll have to compare them to some of my small two ways some time.

Ron

As Bose repair is coming to an end, we just scrapped the drivers that went in those. Repaired many as well as the newer 151 variant.

@Wolf said:

Don't know why I have this fascination with bugs, but I find some of them interesting to watch or find. If I see a bug and I don't know what it is, I can snap an image on the phone and google will find it.

iNaturalist is a great app if you are into plants and bugs. I use it frequently when traveling if I come across unfamiliar plants and critters.

I was going to post this in the 'Drum Test' thread, but it's not quite relevant to that, so here's the great recording engineer Eddie Kramer talking about how he records drums:

That ^ is very useful for me, Geoff even though I use sampled sounds - Why?

Because the software I am using/migrating towards is very sophisticated and contains a full mixer with the same sort of close and far-field microphones in various room sizes for me to mix to create my own sounds/mix for my kits.

As I was discussing off-line with Erik (Analog Kid) once past the mics and onto tape/HDD/SSD - the entire mixing/mastering discipline is the same for both acoustic and digital drums these days.

The current TV commercial for 'Isuzu' 4WD people movers uses Fleetwood Mac's "Go Your Own Way", presumably to suggest rugged independence or some other BS concept.

But if you listen to the song, it's pretty obvious that "go your own way" really means "f - - off", at least, that's the way I interpret it.

I watched "The Final Countdown" again yesterday: a pretty average film, but great footage of aircraft carrier operations and aircraft. Good ending, especially for the dog.

The plot involves the modern USS Nimitz on exercises near Pearl Harbour, which runs into a weird vortex which takes it back to 6 December, 1941. Recce aircraft find the US fleet as it was then and the Japanese fleet steaming towards Pearl.

The interesting question, discussed in the film, is what should they do?

One issue with time travel (if it were possible) is that if you changed events, history would be different and various things and people would not exist.

If Nimitz' aircraft attacked the Japanese fleet, the tragic events at Pearl Harbour would have been avoided, but Japan would have declared war on the US for destroying its fleet. However, the Pacific war would have turned out quite differently, with, say, no invasions of New Guinea, the Philippines and the various islands.

Interesting to contemplate; many lives would have been saved and created by service men and women who survived, and the world would be quite different.

… and where would we have been without George Bailey?

We all have made decisions that have taken us down our own paths, but what if only I had…. Clearly (in my case) not world changing- but interesting to think about.

There are so many, many 'what ifs': as an example, the late President George H Bush, an Avenger pilot, was shot down during a raid in WW2, as were some of his comrades. The President was able to fly some distance from the action before ditching and he was rescued by a US submarine, but others were captured by the Japanese and murdered.

If things had been different, how would that have affected history?

@GeoffMillar said:

I watched "The Final Countdown" again yesterday: a pretty average film, but great footage of aircraft carrier operations and aircraft. Good ending, especially for the dog.

The plot involves the modern USS Nimitz on exercises near Pearl Harbour, which runs into a weird vortex which takes it back to 6 December, 1941. Recce aircraft find the US fleet as it was then and the Japanese fleet steaming towards Pearl.

The interesting question, discussed in the film, is what should they do?

One issue with time travel (if it were possible) is that if you changed events, history would be different and various things and people would not exist.

If Nimitz' aircraft attacked the Japanese fleet, the tragic events at Pearl Harbour would have been avoided, but Japan would have declared war on the US for destroying its fleet. However, the Pacific war would have turned out quite differently, with, say, no invasions of New Guinea, the Philippines and the various islands.

Interesting to contemplate; many lives would have been saved and created by service men and women who survived, and the world would be quite different.

Comments

Any LPG tank valve experts here?

My grill tank just hit empty and a newly refilled tank will not produced gas.

Another new tank does produce gas.

The failed one doesn't seem able to open the spring seal on the threaded connector - must be some internal fault?

Time to pull the Blue Rhino swap.

I fired Blue Rhino/Amerigas via the State inspectors from my property last year and this little tank is from a local LPG company - Probably need to return it to the place I bought from for a replacement.

I suspect you are saying that the tank is faulty without saying it.

OK, got it working just now - it was stored in the garage and it was 97* here today and probably about 130* in the garage where it was stored - got shaken in transit to the grill on the porch - over pressured - locked-out internally.

Had to release the overload by unscrewing the regulator hose connection until it blew off briefly then reconnect to grill.

GTG, now . . .

First one assembled. This was kind of a test to see if I had all the parts and pieces gathered up. It worked as designed👍🏻 Still working on the rear sticker, that's the last piece of the puzzle.

Also, Keith nailed it again with his fine laser skills...

Stopped by the Walmart 3 miles from my house with the wife and kids...

Antron Brown and his top fuel dragster. Three time Top Fuel World Champion! He's on his way to Brainerd MN for this coming weekend's race there. He stopped here to support a local fireman's charity (not a sponsor that I know of). What a super cool guy. We all chit chatted for about 40 minutes about racing, life on the road, starting his own team, his kids, our kids, God, you name it. Love seeing guys like him who are so down to earth and not full of themselves. Will be cheering for him this weekend.

So our ticking time bomb (silver maple) in the front yard has developed a bug issue where we lost a limb 10 years ago. Anyone know what this insect is?

Did a search, and likely confirmed my suspicions. My guess is the green wasp is attracted to the critters eating the tree to get a good meal. Cuckoo wasps came up in the search, but uncertain they are what you actually see there.

InDIYana Event Website

Just like in NASCAR... They don't and have never produced a front engine V8 car that is a two door sedan and rear wheel drive. But if you throw enough money at the sactioning body anything goes. I don't throw any shade towards Antron (AB Racing). If Toyolet is paying the racing bills... there is nothing produced by Toyota on that racing machine.

Thanks Ben. I plan on having this tree removed as soon as the local tree companies slow down. They are all still slammed from the last round of storms and quoted prices would be extremely high.

Don't know why I have this fascination with bugs, but I find some of them interesting to watch or find. If I see a bug and I don't know what it is, I can snap an image on the phone and google will find it.

InDIYana Event Website

I went out to dinner last weekend and walked past the salon that cuts my hair. They were in the process of doing some cleaning and wanted to know if wanted some speakers that they had pulled from the rafters. I said sure and picked up a pair off extremely dusty Bose Model 101 Music Monitors. They look like they have single 3 1/2" paper cone driver in a cast resin box. They have some weight to them.

They don't measure very well. The vocal range is not bad but there's no bass and the highs pale in comparison to my Raal's. ;-) The price was right and I'll have to compare them to some of my small two ways some time.

Ron

Most people know what a 'Spitfire' aircraft is and would probably love to have one, this guy built one!

He used some different construction materials and techniques to the original and installed an Alison V12 instead of a Merlin, so you could argue it's not 'really' a Spitfire, but it looks great and was relatively affordable.

Geoff

As Bose repair is coming to an end, we just scrapped the drivers that went in those. Repaired many as well as the newer 151 variant.

iNaturalist is a great app if you are into plants and bugs. I use it frequently when traveling if I come across unfamiliar plants and critters.

I was going to post this in the 'Drum Test' thread, but it's not quite relevant to that, so here's the great recording engineer Eddie Kramer talking about how he records drums:

I found it very interesting, hope you do too.

Geoff

That ^ is very useful for me, Geoff even though I use sampled sounds - Why?

Because the software I am using/migrating towards is very sophisticated and contains a full mixer with the same sort of close and far-field microphones in various room sizes for me to mix to create my own sounds/mix for my kits.

As I was discussing off-line with Erik (Analog Kid) once past the mics and onto tape/HDD/SSD - the entire mixing/mastering discipline is the same for both acoustic and digital drums these days.

Thanks for posting it!

Tomorrow will be three weeks with no smokes. Already feeling it at the gym.

They say (I don't know who "they" are lol) it takes 21 days to make or break a habit. So you're there man!

I'm going to try to go 21 days without buying anything speaker related.

You'd be better off to start smoking, wait 15 years, then quit smoking.

Willpower! Mind over matter!

The current TV commercial for 'Isuzu' 4WD people movers uses Fleetwood Mac's "Go Your Own Way", presumably to suggest rugged independence or some other BS concept.

But if you listen to the song, it's pretty obvious that "go your own way" really means "f - - off", at least, that's the way I interpret it.

Strange concept for an ad...

Geoff

I watched "The Final Countdown" again yesterday: a pretty average film, but great footage of aircraft carrier operations and aircraft. Good ending, especially for the dog.

The plot involves the modern USS Nimitz on exercises near Pearl Harbour, which runs into a weird vortex which takes it back to 6 December, 1941. Recce aircraft find the US fleet as it was then and the Japanese fleet steaming towards Pearl.

The interesting question, discussed in the film, is what should they do?

One issue with time travel (if it were possible) is that if you changed events, history would be different and various things and people would not exist.

If Nimitz' aircraft attacked the Japanese fleet, the tragic events at Pearl Harbour would have been avoided, but Japan would have declared war on the US for destroying its fleet. However, the Pacific war would have turned out quite differently, with, say, no invasions of New Guinea, the Philippines and the various islands.

Interesting to contemplate; many lives would have been saved and created by service men and women who survived, and the world would be quite different.

Geoff

… and where would we have been without George Bailey?

We all have made decisions that have taken us down our own paths, but what if only I had…. Clearly (in my case) not world changing- but interesting to think about.

There are so many, many 'what ifs': as an example, the late President George H Bush, an Avenger pilot, was shot down during a raid in WW2, as were some of his comrades. The President was able to fly some distance from the action before ditching and he was rescued by a US submarine, but others were captured by the Japanese and murdered.

If things had been different, how would that have affected history?

Geoff

Finally getting the front panels done

According to Einstein, it's possible.

Quite right, but I've heard Prof Brian Cox explain it and still can't understand how it's possible! I need a Geoff-proof explanation....

In a sense, time travel happens when we look at a distant star; we're looking at it as it was maybe many light years ago.

Geoff