I've had bad luck with particle board and router bits. Seems like there is so much other stuff in there other than wood. Seems like every sheet I cut causes significant wear. I have even had sparks coming off the tooling.

Looking great btw.

Yep PB is hard on tooling. I go through a bit about every 18-22 half sheets. Mdf is about 30-35 half sheets. I use a 75% feed rate to save as much bit life as possible.

i am lucky member of maker space that has awesome woodworking tools and shopbot 4x8 cnc router. i still need to learn a lot, especially cad design, but its fun and rewarding. sickening machine.

@hifiside said:

I’m in a build slump. Everything I was looking at building I say (meh) too. 🤷🏻♂️

Go back and take a look at some older Missions, ATCs, and the older Naim’s floor-standers (SBLs), always something cool / interesting (imo) that could use a ‘hifiside’ mod or two…

I would like to see what you come up with for a GRS 8PT-8 PA speaker. Pair that with something like the pro dt175 and a 60x60 horn could make a nice pa/monitor.

Comments

https://www.jfcomponents.com/

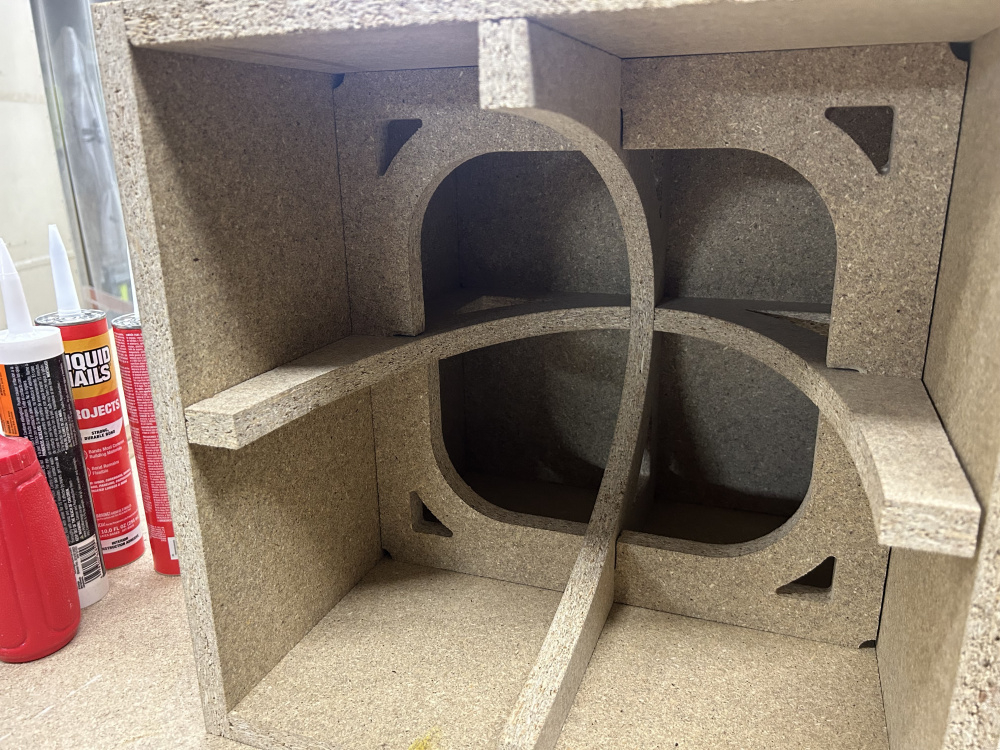

Prototype temporary together for fitment.

https://www.jfcomponents.com/

https://www.jfcomponents.com/

I'm beginning to not like you - ha

Thinking up and fitting puzzle pieces- very nice !

I've had bad luck with particle board and router bits. Seems like there is so much other stuff in there other than wood. Seems like every sheet I cut causes significant wear. I have even had sparks coming off the tooling.

Looking great btw.

Yep PB is hard on tooling. I go through a bit about every 18-22 half sheets. Mdf is about 30-35 half sheets. I use a 75% feed rate to save as much bit life as possible.

https://www.jfcomponents.com/

If you list these nice end tables on your site I'm sure to buy one. That would look great by my arm chairs.

Pizza tables!

https://www.jfcomponents.com/

it looks awesome!

what kind of cnc do you have?

i am lucky member of maker space that has awesome woodworking tools and shopbot 4x8 cnc router. i still need to learn a lot, especially cad design, but its fun and rewarding. sickening machine.

4x4 standard CNC. From here.

https://www.avidcnc.com/

https://www.jfcomponents.com/

Mockup video.

https://www.jfcomponents.com/

Building some car audio cabinets for a local shop.

https://www.jfcomponents.com/

Those are misleading.

https://www.jfcomponents.com/

That's a tiny tweeter!

Beside Mac-04

https://www.jfcomponents.com/

Another show I missed. Just seen it on FB. Next year I guess. Sounds like all vendor room sold out.

https://www.southwestaudiofest.com/

https://www.jfcomponents.com/

In Iowa I mentioned that one and:

https://lonestaraudiofest.com/

Spring cleaning starts.

https://www.jfcomponents.com/

Intriguing design.

https://www.jfcomponents.com/

I'd like to see some measurements on that one. How big is it?

8”

https://www.jfcomponents.com/

Do you have the water based body filler for sale now?

Very soon the ingredients in bulk is killing me on shipping.

https://www.jfcomponents.com/

I’m in a build slump. Everything I was looking at building I say (meh) too. 🤷🏻♂️

https://www.jfcomponents.com/

Go for a hike and get away from the shop for a while . . .

Go back and take a look at some older Missions, ATCs, and the older Naim’s floor-standers (SBLs), always something cool / interesting (imo) that could use a ‘hifiside’ mod or two…

I would like to see what you come up with for a GRS 8PT-8 PA speaker. Pair that with something like the pro dt175 and a 60x60 horn could make a nice pa/monitor.

Yeah do something else for a bit. Nothing ruins things like forcing it.

I will finish our commercial build that JR and I have been working on. I have sat in front of these for the last 6 hrs. Shooting for DDIY.

https://www.jfcomponents.com/

I would like to see you steal my idea of a WTWW 2.5 way with MAC06's all in parallel