Site Links

Howdy, Stranger!

It looks like you're new here. If you want to get involved, click one of these buttons!

Quick Links

Categories

In this Discussion

Who's Online (0)

"Toxicity", my InDIYana 2025 entry...

Okay, yes, I started these today. I've been sick with a chest/head cold this last week, so I had no choice. I've previously stated this would likely be with the TB W4-1052S Neo wide range. I bought the last 2 on this continent I could find from Solen late last year.

The woofer component was hopefully going to be the quad of Usher 8945P I've been trying to unload for a few years. Suffice to say, I didn't know one had a hole in the surround. I fixed that with Alene's a year and a half ago. Still noone wanted them. Another one had something more sinister wrong with it that I didn't know about either. The spider had pulled away all but completely from the frame rim. I found that 2 sheets of printer paper was a tight shim to the center pole, and applied Alene's yet again to that driver with a little weight sitting on the cone to keep it in place. It appears to be holding now, so I'm proceeding with these 4 woofers. The aesthetic is close to the wideband with aluminum phase plug and black cone and frame.

I bought the 0.6ft^3 particle board cabs from Brad late last year too (I think) for this project. Just today, I have made and test fitted the partitions for the wideband and removed the braces that came installed. This left about 15 ltrs for the woofers, and just over a liter for the widerange.

Next up is cutting panels for the port and cutting driver recesses.

Sorry, I haven't taken pictures yet.

The name stems from the theme direction and its difficulty, and the aesthetic direction I'm taking. I'm not sure I'll get the finish done as yet, so I will hold off on spilling those beans. The driver orientation will have the W4 on the top front, and one woofer below. The other woofer will be on the lower rear opposing the front one. Port will downfire in a slotted format.

Filter and alignment thoughts;

The widerange will have a double chamber aperiodic sealed environment to live in, so that will subdue the widerange + box system resonance. This volume rolls off the widerange around 200Hz, and the xmax is fine at 20W and over 100dB without attenuation. I will likely bring the woofers in above there due to Baffle step. Since I'm using a smaller box than optimal for the woofers, the volume will be stuffed to reduce peaking, and I will likely have a 1.5.5 way in the end to bring up the bottom end and flatten the response. I'm sacrificing sensitivity in the midbass band to do this, but I also get twice the power handling due to using 2 woofers. A single in this box will have a vented F3 of about 45Hz, whereas a pair in straight parallel in this volume would have an F3 of 58Hz. F10 is about 35Hz.

I'm hoping the widerange will need some attenuation of output, as it is a 4 ohm driver. The pair of woofers I'm guessing will have large coils involved, and likely increase the net impedance of the pair to above 4 ohms nominal.

Had I not had these cabs already, I would likely not be trying to get these done. I think I have enough time....

Break over, Back to work!

Edit; changed surround to spider.

Comments

Cool project! Good luck getting them done in time. Two weeks to go!

Holy last minute Batman, no pressure...

Snap to it, Ben.

I built the Zingers in 2 weeks and voiced in a 3rd several years ago, this is tighter than that. I'm hopeful.

InDIYana Event Website

Slot ports installed and cut through...

7" long by 0.75" wide slot, 8" in length.

InDIYana Event Website

Okay, I have the widerange multi-chambers gluing as I type this. I screwed a batten to the inner top panel to keep the primary chamber board in place. Since these are angled at about a 30 degrees at the inside baffle, and about 60 degrees at the inside top, it facilitated a place for the gorilla glue to seat and foam around the joint while the bar clamp at the sides of the baffle held the other end in place. IE- insert primary board below horizon, apply glue, move into position, and clamp. The secondary board was glued on on top of it with angled edges mating the inside top and the primary board. The secondary board has 4x half inch holes in it for venting and pushing in some stuffing after glued. The other 5x 1/8" holes facilitate the pegboard clamping screw pilots as I will be clamping the compressed foam over the vent holes. Relative volume is 1ltr total, and divided about 1/3 and 2/3 volume with the smaller in the aft position. The large circle on the main board is centered approximately where the magnet will reside or come into contact. If I have to, I will remove material from this area. Nothing a Dremel can't fix here.

I wish I could find more of this 1/2" thick 9-ply as it is strong and really nice when I'm trying to save space. This came from an old bathroom or kitchen counter, IIRC.

InDIYana Event Website

Menards used to have some 1/2" thick, 9 ply, baltic birch panels that were randomly like 22.5" x 23". They were only $2.55. Had to sort through the stack or two to find the really nice ones but it was way worth it. I bought quite a few but haven't seen them there for about 2 years, maybe longer.

Nice find, shame it is NLA.

InDIYana Event Website

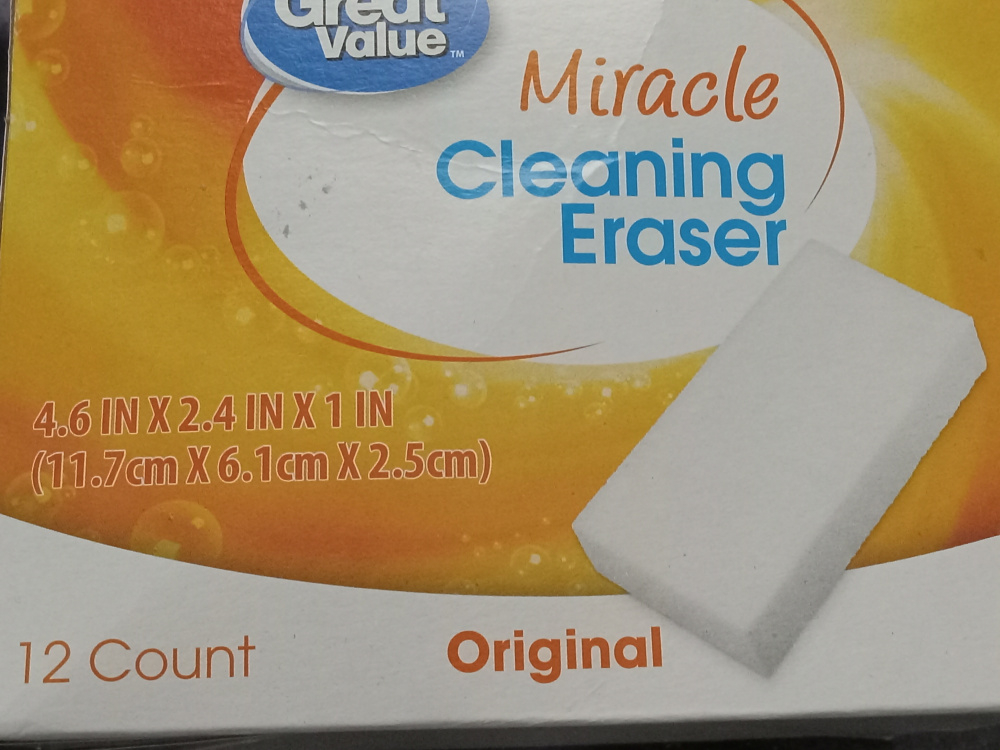

Update, magic eraser melamine foam and pegboard clamp installed. I think I will add washers to the other 8 screws to prevent pull through, not currently shown. The center screw acts as the tensioner and controls how tight the foam is compressed. This way I can adjust the Q of the vent to a minor degree. I have a full 3/4" thick off brand eraser underneath. There is a glue bead between the perimeter of the eraser and the secondary partition board.

InDIYana Event Website

What does the magic eraser do? Is it just open celled foam or something else?

It absorbs sound pressure waves inside the cabinet.

Cleans up the response

It erases over excursion.

Home brewed aperiodic port!

Yes, it is just a simple DIY aperiodic vent into the secondary chamber.

InDIYana Event Website

So, what is your thinking / goals with this?

Some are just open cell melamine foam. Some others have a detergent additive or other agents for cleaning better. For use in speakers, obviously the plain original foam only type is preferable.

It is a very light mass open cell melamine foam with decent density. You can actually breathe through it. I find it is not that great as enclosure damping, but as a flow resistant foam it is probably a good choice. The clamping or compressing of the foam increases the resistance to flow as well as making the seal more robust to function as intended. The measured impedance will show whether it works well or not.

InDIYana Event Website

The multichambered aperiodic sealed alignment is known to reduce or minimize the driver's inherent resonance and lower Qts. As such, it reduces the driver's tendency to get excited and increase excursion in this problematic range. I find it also can make for a well damped box for midranges, taking the box out of the sound.

InDIYana Event Website

Is that better than sealed or in between sealed and ported?

You get some cone control of sealed, but a sealed chamber will resonate around a certain frequency because the single unimpeded volume of air acts like a single rate spring. The leaky nature of aperiodic deflates that resonance a bit because it bleeds off some of that energy into a seperate chamber.

Ported I believe actually acts like a sealed enclosure above the port tune because the slug of air in the port has enough inertia to resist moving at higher frequencies. I figure that is why a ported enclosure has two peaks in the electrical impedance. One for the interior volume resonance, and one for the resonance between the port and the interior volume once it is 180deg out of phase with the cone.

a-periodic= non periodic. As in, does not resonate at a specific frequency. The electrical impedance should look more like a hill or hump rather than a spike/peak. Us humans tend to notice differences more if it sticks out like a peak. If a resonance is reduced and spread out we tend to notice it alot less. Sealed/ported were originally intended as methods of gaining more bass vs an open back box. If attaining bass from the driver is not the main goal that changes priorities.

My entry, using two small aperiodically vented pipe sections, reduces the main impedance peak all the way down to two or three smaller 12 to 15 ohms bumps. The Qtc, according to DATS, comes in at about 0.65. The small, sealed PVC enclosure, for comparison, has a single impedance peak of nearly 50 ohms and a Qtc of 1.2.

Progress....

Today, I did quite a bit. About 6 hours worth of work plus drying times.

1- veneered the baffles and backs, which is a first for me.

2- after the contact cement dried, cut driver holes and rebates, drilled mounting holes, and relieved the back of the wideband holes.

3- applied glue and clamped both to each cabinet.

Tomorrow, I hope to figure out the feet and maybe, just maybe, veneer the rest of the cabs after I flush trim the baffles to size.

InDIYana Event Website

Attached some at least preliminary but maybe final feet, flush trimmed the edges, and cleaned them up as much as possible. The rest of the finishing will have to wait. I bored holes for input terminals in the feet to keep the back panel cleaner. I need to bore for widerange and woofer wiring and then can set upon trying to measure and voice a hopefully simple xover. Just wanna bring em this weekend....

InDIYana Event Website

InDIYana Event Website

Cutting it tight aint ya?

Yep, good thing I'm off Wednesday and Thursday too.

InDIYana Event Website

Ben, I sent you a DM.

You did? Where?

InDIYana Event Website

Proof in the pudding...

The W4-1052 had an Fs of about 80Hz, and a magnitude at Fs of 35-40ohms depending on which unit measured.

The first measured in the cab has a magnitude of 16 ohms at 150Hz.

I'd say I suppressed that pretty well....

InDIYana Event Website

InDIYana Event Website