Site Links

Howdy, Stranger!

It looks like you're new here. If you want to get involved, click one of these buttons!

Quick Links

Categories

In this Discussion

Who's Online (0)

Barium - Small two-way with Atlas ribbon and SB ceramic woofer.

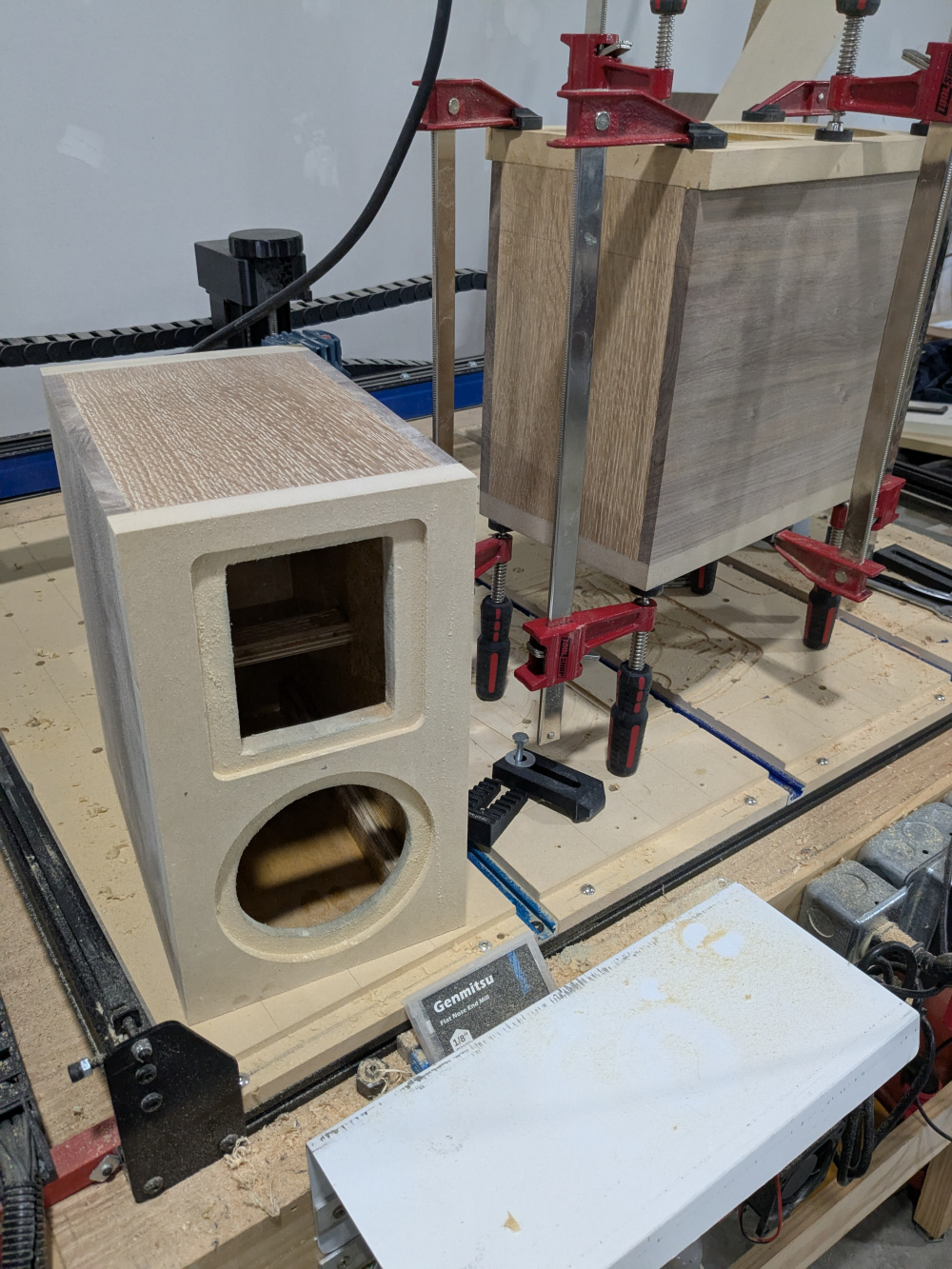

Named from the Greek word meaning “heavy,” Barium is a soft, silvery-white metal. This small ~ .25ft^3 two-way will feature the recently released RAD Atlas AR120 tweeter paired with the SB Acoustics SB12CACS25-4. Cabinet dimensions will be 11.5" tall by 6.5" wide and 10.5" deep and will feature walnut sides, oak tops/bottoms, and painted front and rear baffles. The woofers were exercised today with hopes of some basic T/S data collected soon. Cabinet pieces are in the process of being cut. The baffles will be .75" MDF while the tops and bottoms will be 5/8" scrap oak flooring. The sides will be a sandwich of 1/2" particle board and 3/8" walnut. More to come...

Comments

Cutting and trying to flatten a bit of cupping in the walnut.

Baffle CAD with 1/2" chamfers.

Glue up has started.

Each and every speaker project reminds me that I'm not much of a woodworker. After struggling with getting the top, bottom, and sides squared up I was able to glue up the first one and flush trim the walnut.

Your not the only one. I'm just getting better at covering up issues.

Me too. A master woodworker told me "Just make it look good from 6 feet"

Unless you are feeding your family from the work, the result is all that matters.

I like your choice of wood.

That's looking pretty good to me!

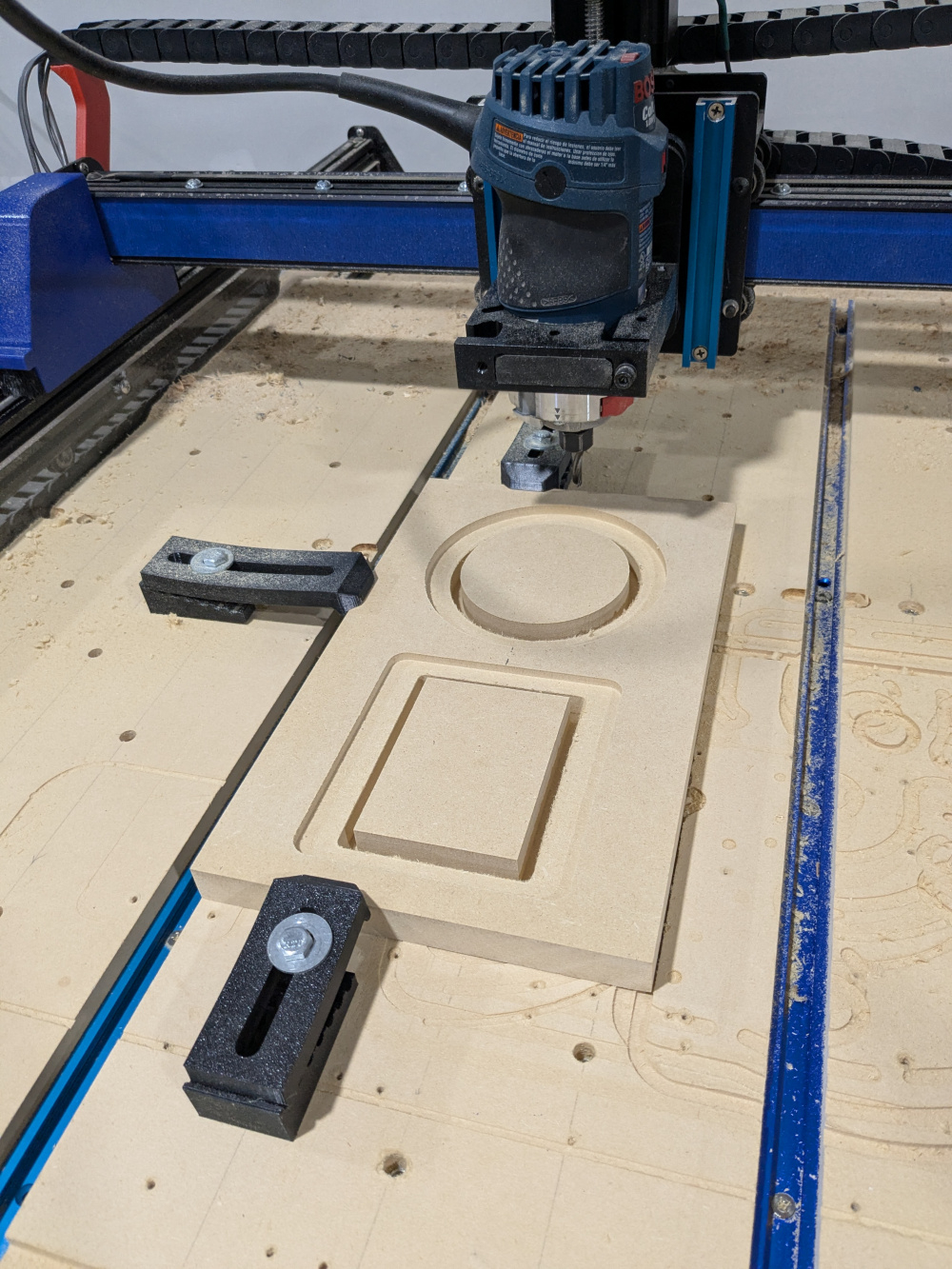

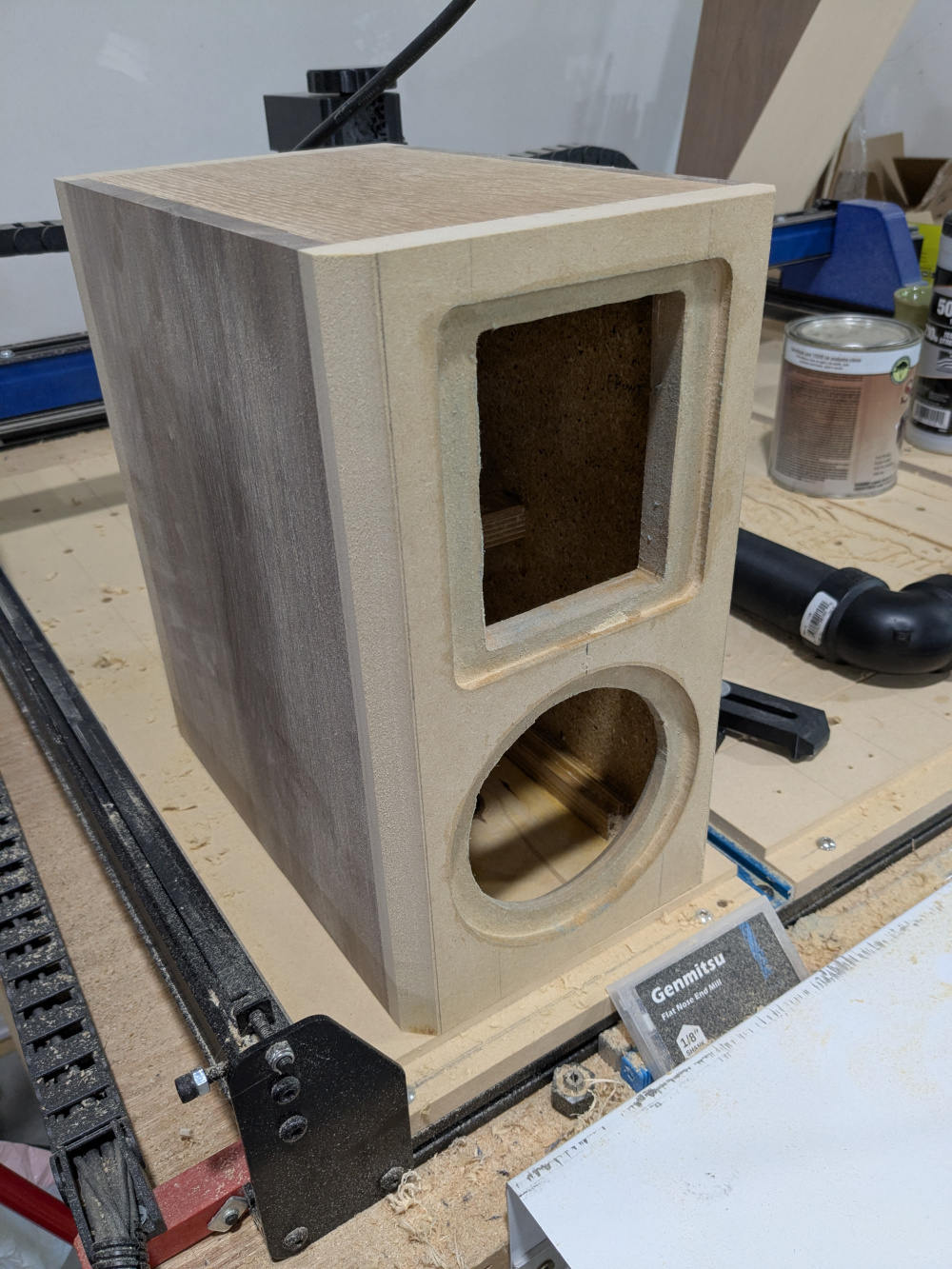

First final baffle off the CNC.

Curious if your top panel feathers a bit after some stain/finishing.

I effing love using a CNC for baffles. I often made booboos with a router.

I appreciate the comments, let's hope the glue holds

I had to calibrate the CNC as my Y axis was right on, but my X axis was a just a bit short. I'll be doing hard wax oil for the finish. I'll shellac the MDF and then paint it.

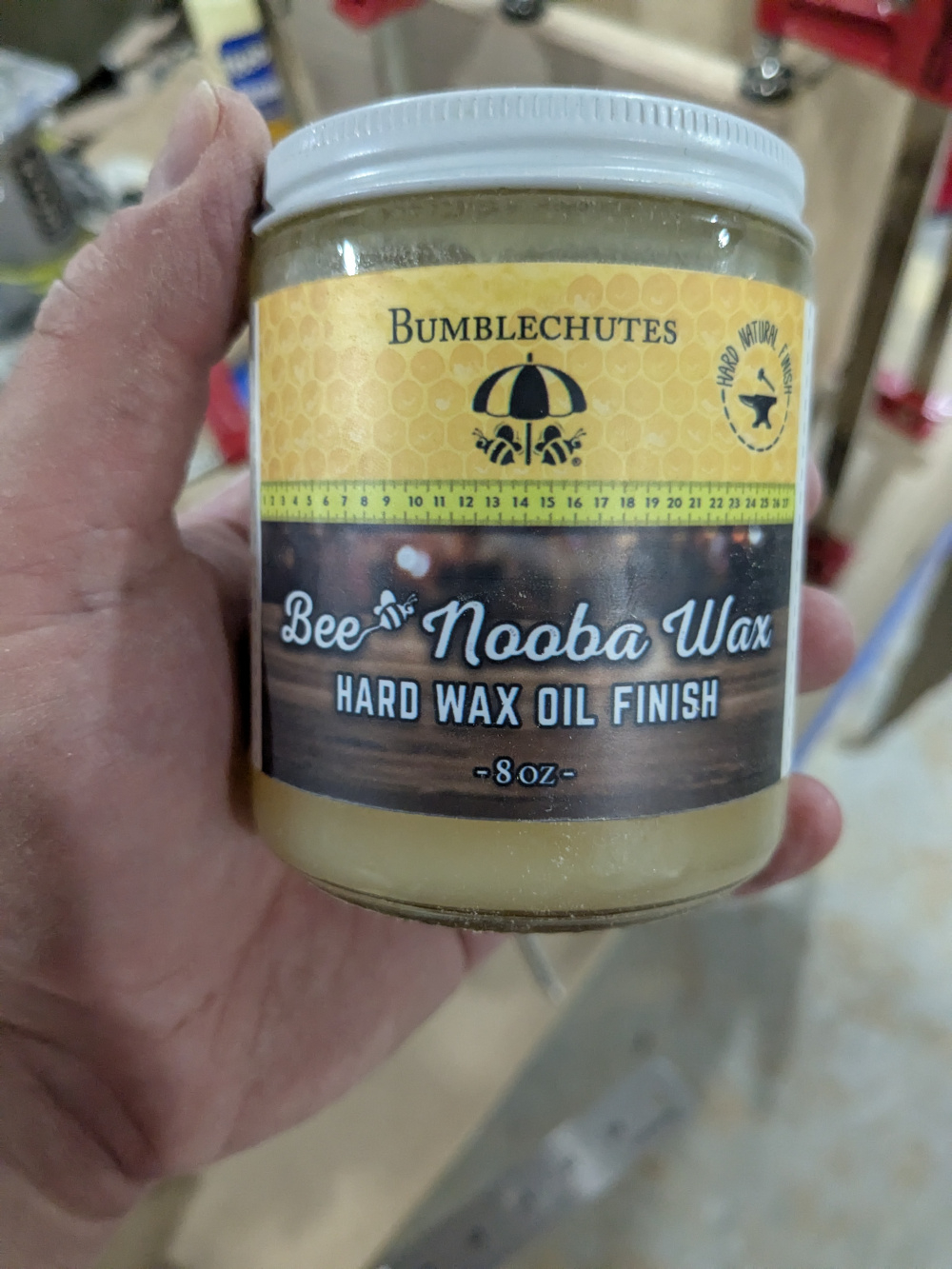

Which hard wax?

This wax. Started the second cabinet and glued the back on the first.

Thanks. Had not seen that product.

I have used a lot of Tried and True finishes.

Just direct wax, no other sealer? I use hard wax, but once I have sealed with shellac or a water based finish like generals

Yep, from what I understand, the hard wax oil needs to soak into the wood. Flush trimming the back on one and putting the other side on the other.

The first cab has all six sides... hurray!

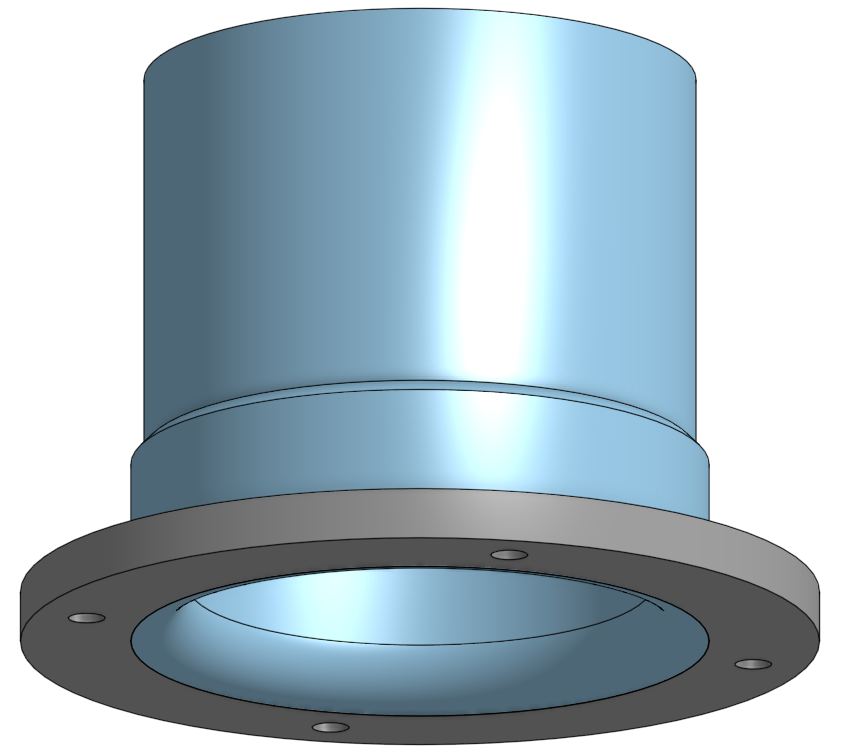

CAD'ed up and now printing the ports which will use 1.5" ABS elbows.

Both now have baffles and one has been flush trimmed. I still plan on on adding the chamfer to the sides of a baffle.

That should be a nice driver combo. I think they are going to look great! Hope with their smaller size that you don't experience any issues with the hardwood's movements in different directions with temp/humidity changes.

Thanks. I hope that since the oak is plywood backed flooring and that I glued the walnut to the particleboard, I'll have better luck....fingers crossed.

Not quite a friction fit on the elbow, upping the diameter. Verified the fit for the 2" hole in the cab is good. Actual inside port diameter is 1.6" by 9" long.

Both have their 2-in port holes drilled and one has been chamfered. Waiting on my 15/16 forsner bit for the speakON connectors.

Got the baffles painted the same color as the living room cabenets - Cityscape.

Applied the hard wax oil and waiting to buff it out.

Wow, quite the contrast! Cool grey/blue color!

I can't wait to see how cool they look with the Atlas tweeter and white CAC cone woofers. Should be striking!