Site Links

Howdy, Stranger!

It looks like you're new here. If you want to get involved, click one of these buttons!

Quick Links

Categories

In this Discussion

Who's Online (0)

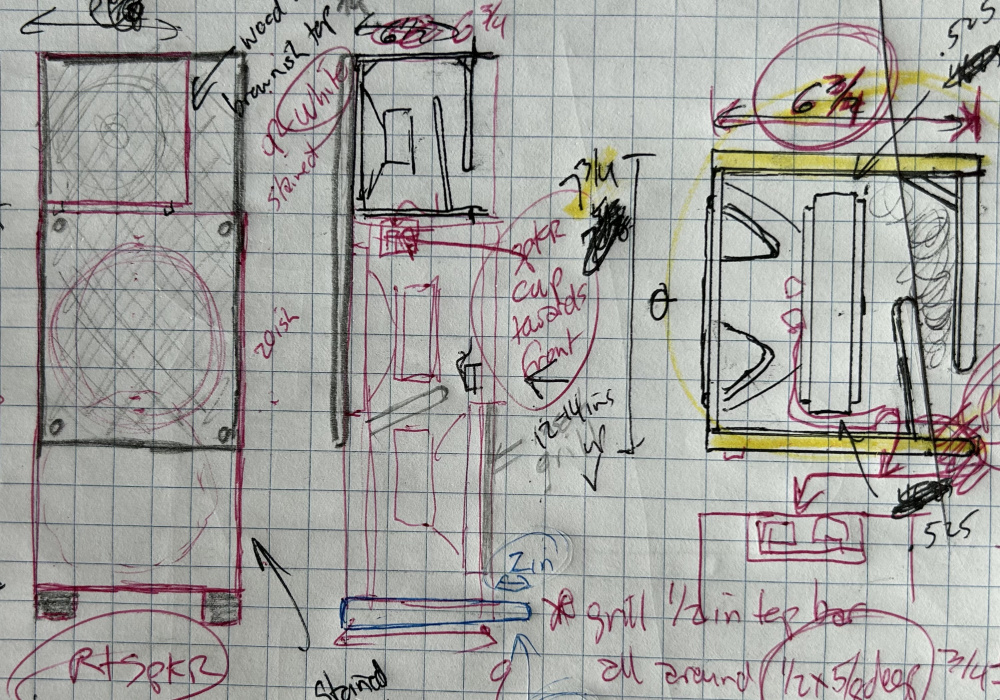

1.5 way sealed bass, top box interchangeable

Finally, finally making sawdust.

Going back to a two stacked box build where I can change out the top (broad ranger, coaxial, or mid / tw separates).

I’m now ‘sold’ on sealed woofer(s) so going with a pair of 8in sealed 1.5 way set-up with the .5 rearward facing. Easy enough to incorporate via active, with interchangeable passive top(s).

Top box; while I recently built an ~open back/side Celestion coax, I’m starting with my old friend- an Audio Nirvana Super 6.5. It’s a very solid, cast aluminum framed, broad ranger with excellent extension. So keeping it ‘simple stupid’.

I may down the road try a Markaudio / super tweeter combo (beyma slot or fostex super tweeter) as this image is ‘calling’ me.

Comments

What is "this" image.

On the other hand are you doing any timing difference for the rear 0.5? Interested to see the results. Would there be any cardioid benefits?

Didn't see a description (just the image). Looks like a fostex FE168EZ, not certain of the ribbon (could be a fountek?), possibly a 12in W.

Re the 1.5 woofer box, I'll definitely post when I get there. I'm just thinking potential benefit of offsetting forces front-to-back in a bipole configuration, and the .5 being a 4pi radiation pattern in its frequency range, so location indifferent. Not looking to do a cardioid as they will be played as bipoles, however interesting though if ran as dipole one could play with the .5 level, as well as delay.

Woofer is a SS paper Revelator, and tweeter is a Fountek Neo CD1.0. Size comparison looks like the Fostex is a 4 or 5".

InDIYana Event Website

https://www.fostex.jp/en/products/fe168eσ/

Luckily you're not going to use that Fostex driver as a full range! I wouldn't even publish that frequency response if I was Fostex. Note the 10 dB/div scale

Pretty sure it's this one...

https://www.fostex.jp/en/products/fe108eσ/

InDIYana Event Website

Thanks, I didn't know they had made a 108 version.

The fe168 is out of production (and yes it would take a few notch filters to straighten it out, if then). I just thought it was an interesting cone design (and didn't know they made a fe108- thx Ben). I'll be using my AudioNirvana's for starters. But in any event the Markaudio's look to be better broad rangers then the fostex, at least vs the fe168

There was a 208 as well.

InDIYana Event Website

I’ve got the top vented boxes put together (not yet felted / foam lined). Tuning with vent open ~ 180ish, with a bit of foam ~ 120ish, which should work out just fine as I’m at this juncture targeting 1st O HP in the neighborhood of 180-240Hz.

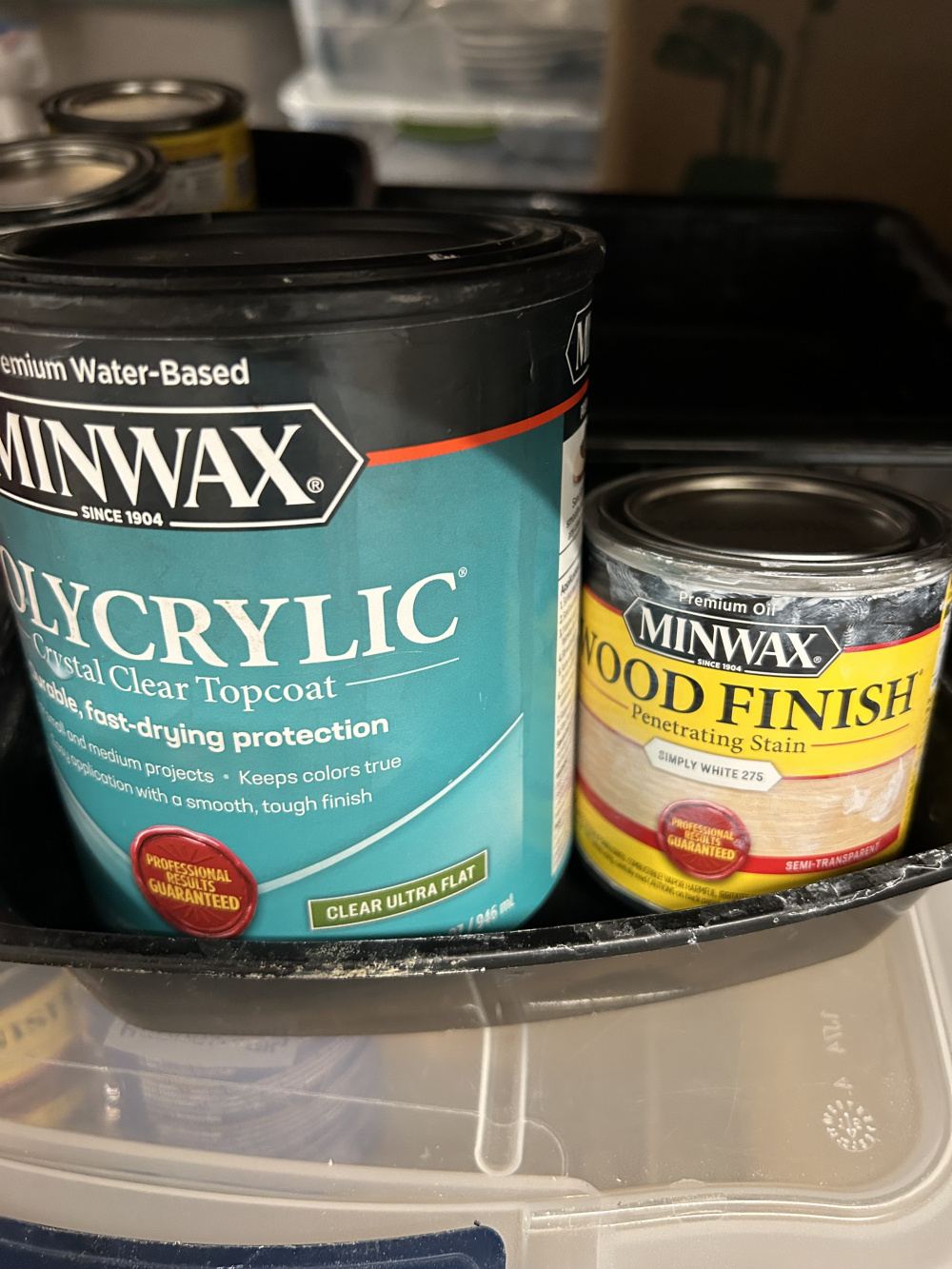

I’m going with a black stain / flat topcoat for the bass unit (Baltic birch) which, per a couple of test pieces, lets the wood grain show through a bit through the black.

I’m looking to stain the top boxes white (with a flat topcoat). Gave it a go and found that white stain doesn’t really do much of anything to the Baltic birch.

So, I’m thinking maybe I need to mix some white stain or paint directly into the flat topcoat to move this towards white? I want the grain (what there is) to show through similar to the bass unit (so not wanting to just paint white).

Suggestions from you guys with painting / staining experience would be appreciated.

If you want white with some woodgrain peeking through, a white wash would do it. That is what I did on my TV stand. I did a roughly 50:50 mix of white primer to water ratio. Brushed on one coat. If you want less white and more grain, you can use more water/less primer. And/or you can also wipe off excess to reduce the white, like you would stain. But I bet you gotta work quick to do that since it dries quickly. Then finish up with water based polyurethane to seal it without turning the white yellow.

https://diy.midwestaudio.club/discussion/2435/tv-stand/p3

Who said water (based) and oil don’t mix?

I finished up the broad-range box; lined, and lightly stuffed the vent (tuned to ~the driver's free air Fs, which will actually be below final Xover frequency with woofers). I'll be placing some white felt in the corners of the baffle.

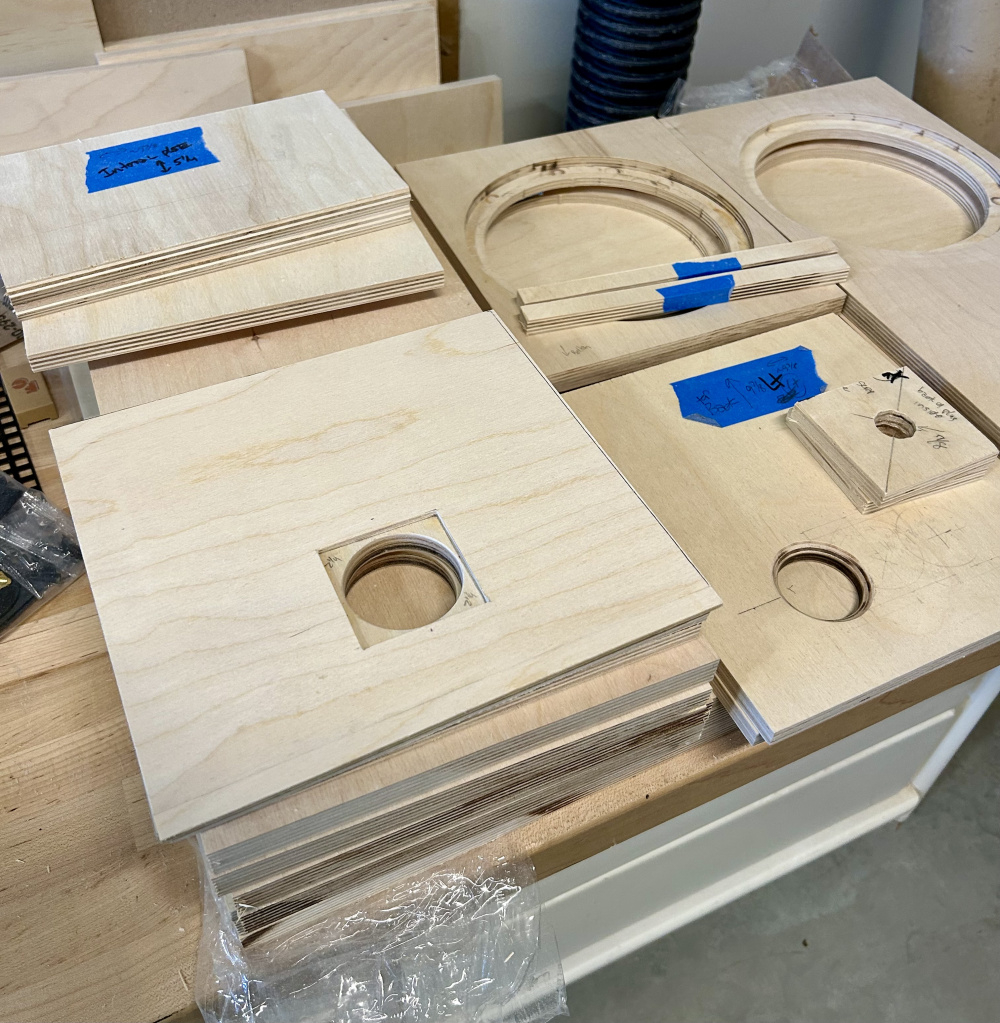

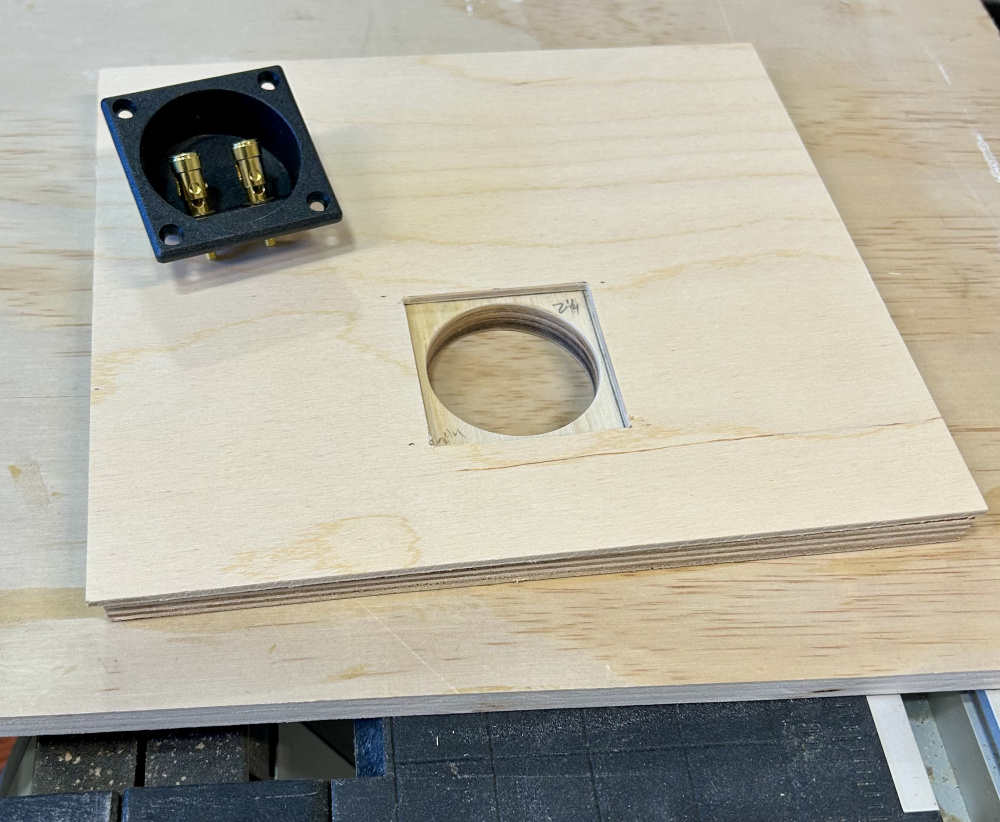

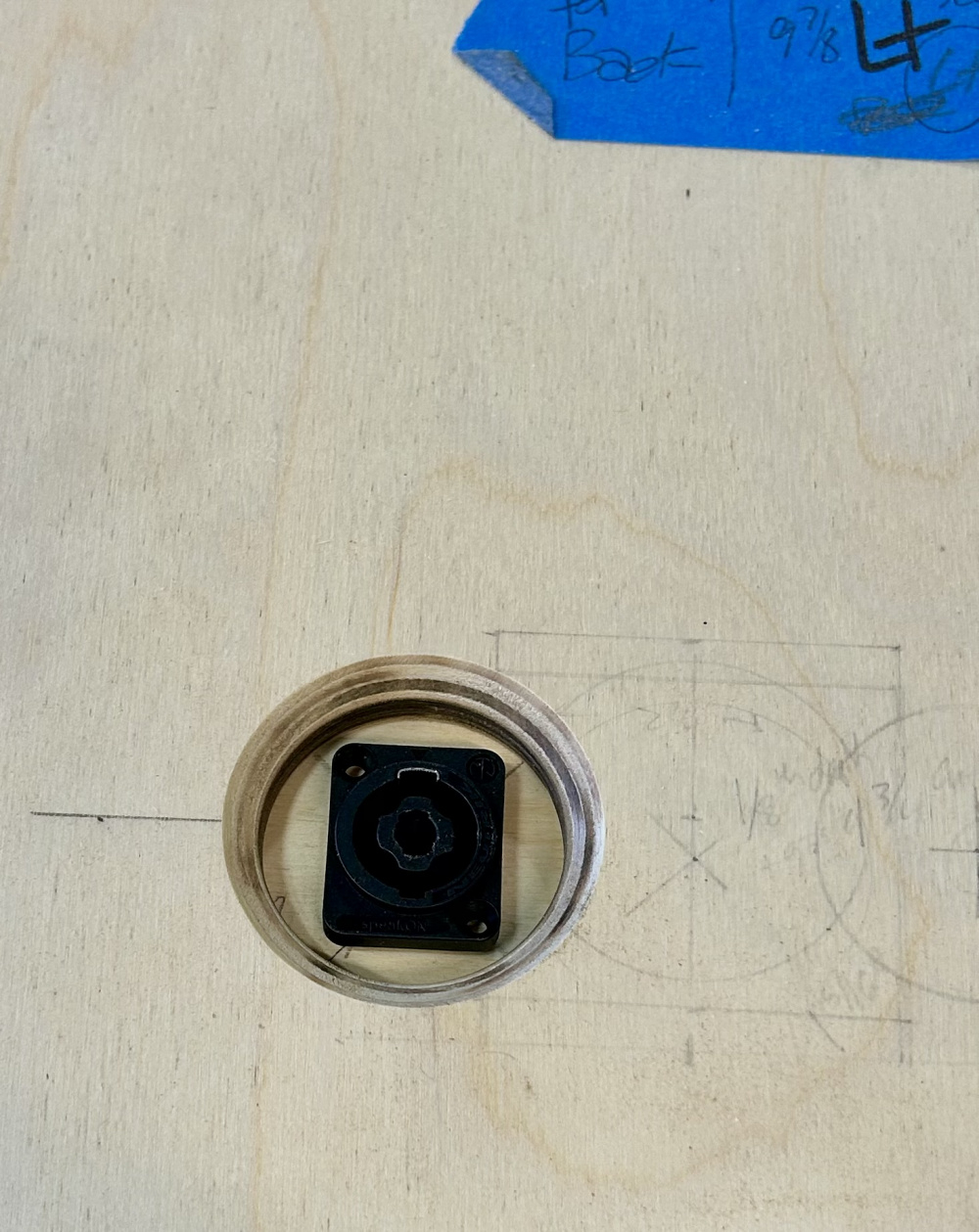

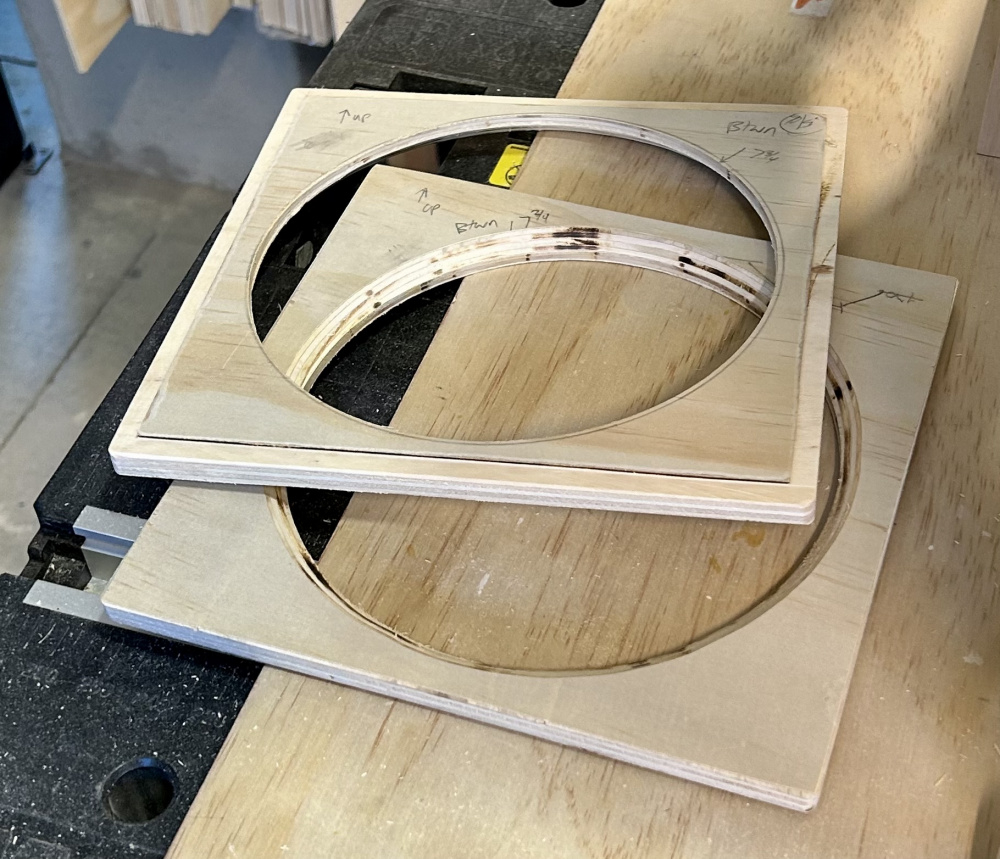

Mostly done making sawdust, all pieces cut. I'll just need to trim the top of the woofer box as I flush mounted the binding post (for the broad-range which will sit on top). Instead of making a big form for a router, I found it easer to cut the small square out of a ⅛ inch sheet of BB ply and glue it to the top board. I'll just need to flush trim it. And set-in for the speakON 4pole.

I need to buy a few more clamps !

Glue up time. Being patient enough to let the glue dry is one of my (many) weaknesses. But I do need to head to ACE for more glue…

Waiting for coils for the .5 way to come in, I at least was able to get the stands made (~ 4.5 to 5 degrees upward tilt). And ‘borrowing’ from Ugly Woofer, I cut and routed what will be grills for the back facing .5s. Hard to see in the pics, but the backside of the grills were run (vertically) against the table saw guide to create space for the grill cloth when wrapped around and glued (thx Nick).

Getting close to gluing up the final sides. While not covering all of the interior with absorbing materials, I try to a) get the first reflection areas (more off the sides of the drivers), and b) generally use a few differing materials/ thicknesses. Just a hunch ?

Also, personal lessons learned- skip the self-adhesive felts. Gluing gives opportunity to move the material around a bit. The first batch of self-adhesive I ordered from Grainger wasn’t bad, but this second batch sucked- the sticky stuff pulled away from the felt.

And, I’ll never bolt in my speakers again. This build I’m pulling drivers from two prior builds and don’t know how I got the bolts on in the first place - kinda tight in the corners. Going with wood screws going forward- easy enough to add a bit more wood at the back of the baffle where the drivers will screw in (glue and a couple of pins) and, I think wood screws hold better.

Hey Grok 3…submitted a question.

Response (trimmed down)

To determine the f3 and f6 for the described system using two Dayton Audio RSS210HO-8 8-inch subwoofer drivers in a sealed enclosure, I’ll analyze the setup based on the provided parameters, driver specifications, and acoustic principles. I’ll calculate the response for both the un-EQ’d case and with a broad 3 dB boost at 35 Hz.

System Overview

- Drivers: Two Dayton Audio RSS210HO-8 (8-ohm) subwoofers, wired in parallel (resulting in a 4-ohm nominal load).

- Enclosure: Sealed, net volume of 0.70 cu ft (19.8 liters).

- Driver Placement:

- Front driver: Mounted high on the front baffle.

- Rear driver: Mounted low on the back baffle, with a 4.0 mH inductor creating a low-pass filter.

Parallel Wiring:

- Two 8-ohm drivers in parallel yield a 4-ohm nominal load.

- Combined sensitivity increases by ~6 dB (3 dB from doubled cone area, 3 dB from halved impedance), so ~90.5 dB

Driver Placement

- Front (High) and Rear (Low): The front driver high on the baffle and rear driver low on the back creates a pseudo-bipolar radiation pattern. At low frequencies (<100 Hz), where wavelengths are long (e.g., 11.3 ft at 100 Hz), the placement has minimal impact on f3 or f6, as the sound is omnidirectional. The rear driver’s output reinforces the front driver’s in the bass region, maintaining the calculated response.

Effect of EQ

- For a Qtc ≈ 0.7 system, a broad boost can lower f3 by approximately 10-20% (depending on Q and boost bandwidth), as it counteracts the natural roll-off.

Using simulation approximations (e.g., WinISD or BassBox Pro for sealed systems with EQ):

We’ll see how this pans out…

Following up with another Grok inquiry regarding recommendations for selecting best LP filter for implementation of broad ranger with woofer (considering HP active/passive implementations).

Summary

High-Pass Filter for Broad-Range Driver:

• Active 4th-order LR high-pass at 80 Hz (phase: ~0° at 380 Hz, +180° at 80 Hz).

• Passive 0.011 µF capacitor line level (~380 Hz, 1st-order, phase: +45° at 380 Hz).

• Total phase at 380 Hz: +45°.

Recommended Woofer Filter:

• Active 3rd-order low-pass filter at 380 Hz (phase: -135° at 380 Hz).

• Invert woofer polarity to align phases (180° difference → 0°), ensuring flat summation.

Phase Issues:

• The 180° phase difference at 380 Hz is corrected by polarity inversion.

• The 80 Hz LR filter has minimal impact at 380 Hz, and the 80–380 Hz region should have reasonable phase coherence due to the woofer’s low-pass filter approaching 0° phase at low frequencies.

I’m a fan of minwax polycrylic ultraflat. Water based, goes on easily with foam brushes (I’m not set up for spray finishes), and drys fairly quickly for follow-up coats. Hard to see in pic, but the finish is fairly flat - a slight sheen. The stain was black oil based (no pre-stain applied on Baltic Birch, and let dry for 4 days) leaving some grain to show through- I’d call it somewhere between dark brown and black (should ~match our floors).

Nice grain for Birch.

Grills done. Just need to clean up / tie up the interior wiring and mount the woofers - then it’s ‘voop’ / measurement and listing time to get the boxes’ filters (passive line-level HP, and active) integrated. The back woofer grill is velcro attached - bottom outside grill I’ve placed a small nylon strip for easier removal. The front baffle grill is magnetic.

just don't look to close

Haven’t yet had time to set up passive line-level HPass for broad-ranger top box, nor any measurements- just wanted to play some music.

At this time using miniDSP for Xover LR @ 380Hz, with top-box down 8.6dB (guesstimate efficiency offset). I’ll try not to screw things up with EQing when I get around to measuring 😆

I’ve got a lot of listening and tweaking yet to do with overlaying active filters relative to the passive line-level for the top box AudioNirvana, (the fun / easy time) but I’m pretty happy that the line-level high-pass filter (two orange drop 715P 0.022s in series) laid down right on top of the miniDSP’s active 1st order HPass @ 380Hz test/comparison measurements. Would have been easier to stick with all DSP for the crossovers. But, I wanted to try the line-level, as they do provide some protection for the AN driver (turn on / off pop issues) on top of the Furman sequencer, which is set to turn on the miniDSP prior to the amps. 1st order HPass, 3rd order LPass with inverted woofer (net aligned phase).

BTW, the ‘much better half’ is not a fan of the white stained top box. It ~ matches the walls while the bottom box ~matches the floor. I’m thinking it’ll grow on her 🤞.

just delivered 😁

I’m looking forward to comp’ing ESS Heils (Xover ~800ish, 3rd O HPass with 1st O LPass to ~match phase at crossover) vs the AudioNirvana (Xover ~380Hz) as toppers with my 1.5way woofers. I plan to notch out (active with narrow Q) the metal cone woofer issues @ 4.5kHz & 7.1kHz, which in any event are approximately 2 ¼ + octaves above the Xover frequency and down dB significantly at that range.

I recently acquired a pair of older ones myself. I have yet to check them out....

InDIYana Event Website

I had to get these up to start listening…

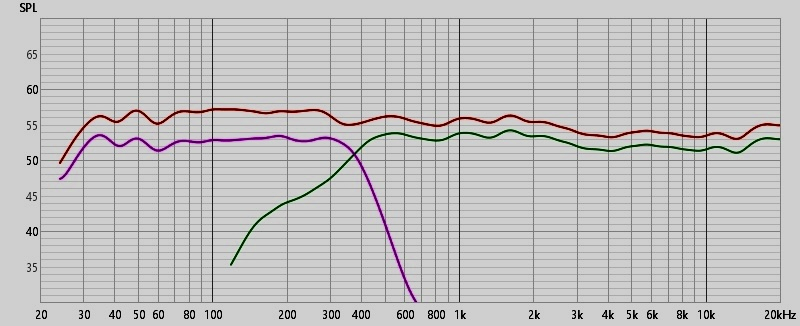

Far from perfect eq’d at this point, but got the ESS / woofer crossing a bit above my tgt of 800-850Hz (need to bring woofer filter down lower, should also reduce rise ~1000Hz area). Also will need to get the frequencies / gains of left spkr (the ESS / 1.5 woofer) more in line with the right spkr for listening/ comparing.

Initial reaction > and probably biased by knowing what’s behind the grills, the Heil ESS is airy / clean. The Audio Nirvanas, while not lacking at the high end, seem to have an edge 380- 800Hz over the RSS 210 HOs ???

Listening to both as a combo kinda works.

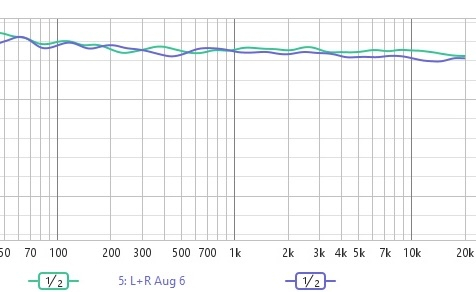

Purple - rt spkr with Audio Nirvanas

Teal - lt spkr with Heil ESS (which I need to pull down a bit for better listening comps)

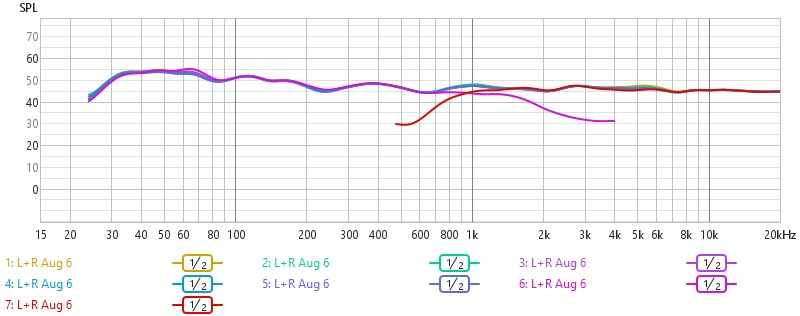

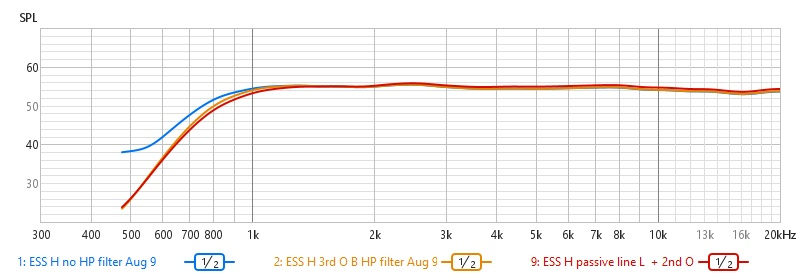

I ran a comp of an active 3rd O Butterworth @800Hz vs an active 2nd O Butterworth @800Hz on top of a passive line-level (two 0.01uF SONICAPs in series ~ 0.005uf, I surprisingly had on hand).

Thought is to provide some add’l protection for the ESS Heils at turn on. Blue: no hp filter. Yellow(ish): 3rd O active. Red: combo.

What are your thoughts dropping the ESS that low ? Any issues cranking up the dB on the source ?

Curious

PureAudio runs their open backs at 700 Hz 1st order series. I emailed ESS and they say that may be a bit aggressive, and recommended 2nd order 800Hz high-pass (which I believe is what they use on their speakers as well). I’m simulating 800 LR2d and looking at levels down 10, 20, and 30dB vs a 3rd order Butterworth- goal to stay above the LR’s.

Actual cross to woofers at this juncture ~ 900 (down from 950). I don’t expect to go below 850.

I’m hoping not to have to learn how to replace a diaphragm 😆