@PWRRYD said:

…my own left brain really likes the Niam look too, the light wood colored one. The all black one kind of looks like a guitar half stack (amp) to me.

I do like the contrast of the wood against a black grill, but to fit into our living room we need darker and/or a weathered grayish walnut look? I’ll be using baltic birch and will play around with finishes. Maybe like my previous build with a bit of gray stain tossed around? I’m also thinking maybe just a wood lower front (barn weathered look) and top, and sides and back black?

So far thinking: top section (with ~open back coax offset) separate unit, providing a small bit of disconnect from bass unit (rubber footing).

Bass section one box, but with indent cut separating angled baffle from sq bottom ‘box’, as going with sealed bass vs double bass unit as per Naim DBL.

Top cap and front bottom sections weathered / stained, balance probably black stain with flat topcoat. Debating if base plate black or weathered stained, and if top plate and front bottom carries through the sides, or if terminated to sides (ie should sides go to front edge?).

My last few builds have been darker walnut’ish stained sides with the balance black (front black cloth grill, with the top, bottom, and back black rolled duratex), which I tend to like, and works for my living room.

I’m leaning black (albeit a bit towards a pro stack look) with top cap and base a weathered gray/walnut. Not really going out on a limb here - but I’ve liked the look of the Vandies.

OK, now that I have use of a DELL I'm able to run impedance via DATS V3 (never used the system, it had been in the basement gathering dust, as not iMac friendly).

I've attached two pics; one for the Morel MW 1058 (open air, lifted off of table for venting). It looks like Re, Qes, Qts, and FS across-the-board are close to, but slightly higher than listed specs. Any comments, and how would a period of break-in affect these (if any)?

The other is for a Celestion 6in coax measured in its open-back 'box' with its passive crossover (3rd order HP on tweeter, the mid is run full without a filter). FYI I run this coax via an active HP ~360 to 380Hz, but for this sweep it is run full. Since in the past I've just run frequency sweeps for my Xover designs (and listening adjustments) what can you guys tell me about this? Thanks (DATS newbie).

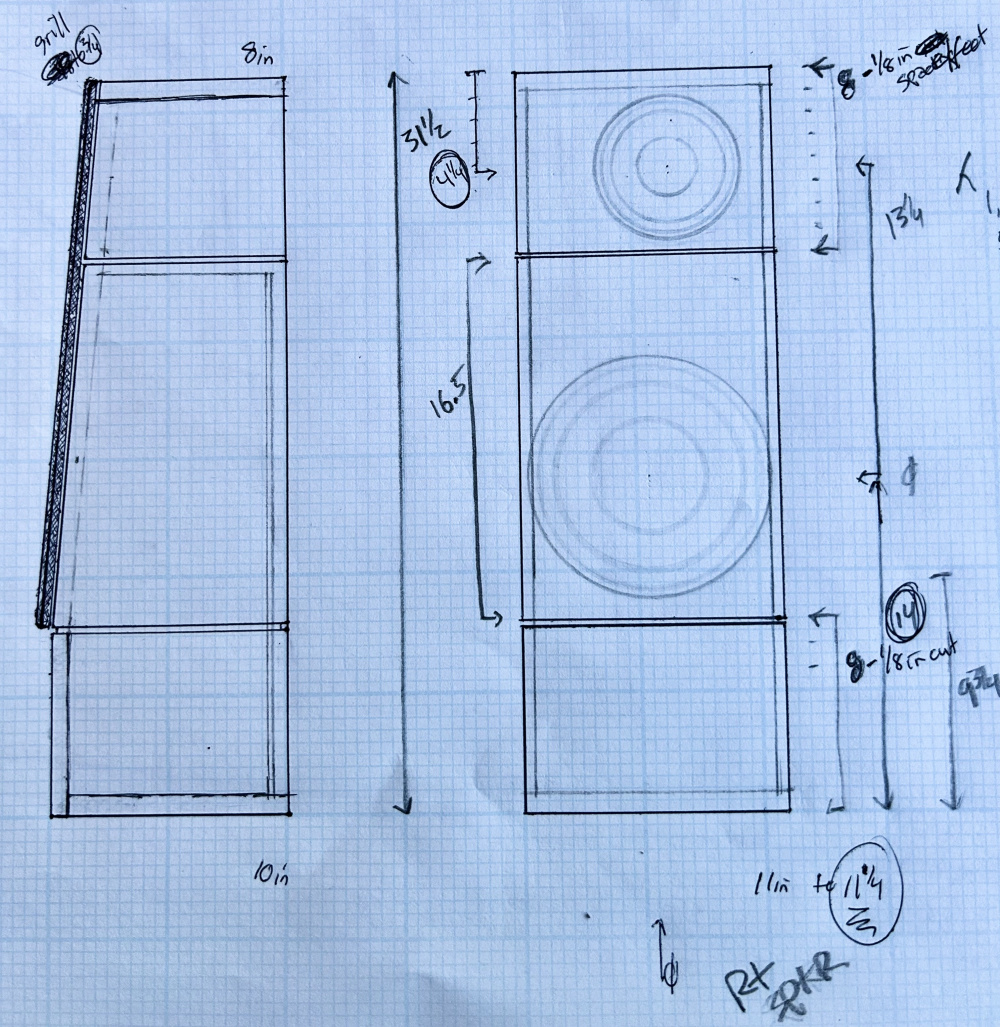

Since I have a nice stack of ⅛ Baltic Birch to laminate a curve, I’m going to toss in a curve somewhere (outside of baffle- mirrored, or at least the back). Here’s the latest (to be placed on low angled stands). Leaning all flat-black stained with ‘aged’ top and base walnut. But still scratching my head.

Nice, I also often use 1/4 inch graph paper. I think about form and function, and if a form could possibly serve a function. That would be the best. Not sure about the rear curve, but it could be beneficial. Not sure. Front curve is all about form. I like it best. Needs a function, diffraction maybe

@Eggguy said:

Nice, I also often use 1/4 inch graph paper. I think about form and function, and if a form could possibly serve a function. That would be the best. Not sure about the rear curve, but it could be beneficial. Not sure. Front curve is all about form. I like it best. Needs a function, diffraction maybe

I could proffer a couple of functional advantages, but primary goals are a) minimizing size appearance (per set volume for sealed 10in woofers), and b) to add a checkbox to trying something new (I did kerfing in last project, this one I'll be laminating 1/8in BB ply for a curved piece). I'm fine with my previous builds using 8 ½ in woofers, going to 10s size-wise for our living room is a bit of a stretch, but when I saw the Morel's... better to ask for forgiveness.

@Tom_S said:

Maybe I misinterpreted your drawing on the right side. I thought one option was to have a curved back.

I could use either of the top pics (your pic), ½ to form the back curve. Top right is ~ as I’m shooting for in my top right drawing. May take a look at ½ of your top left- i.e. deeper bottom section and narrower top - could work as well.

Thx

After measuring (DATS) vs co data, I sent the one woofer back for a replacement. Fs ( 39.64 Hz) looked a bit out from the company specs and from the other driver.

And here’s my latest configuration. I’ll target more of an open back / vent this time around and leaning towards a full black rubbed stain with flat (or semi) sealer. Tried a few samples for an aged top and base - not working for me.

I seem to end up with full scale drawings on grid and cardboard > helps me visualize the build, and often shows issues I’ll need to manage before I’ve created to much sawdust (and blown thru expensive Baltic birch).

@Billet said:

Try leaving the top and bottom open? Just a thought...

The woofer will be sealed (with possibly a bit of eq), just wanting to not box in completely the mid / coax...but could run the front grill up and over the top?

Latest squibbles ~ 5 ½ in ‘frame’ black stained (semi gloss) with back duratex curved back enclosure set just inside. Creates vent for mid of coax (beyma 5 in) at top just under top cap.

Debating slight curved baffle. This would create a very difficult match to the back section - not sure if I can pull it off ? Probably best to stick with pure rectangular baffle.

@6thplanet said:

Is the "vent" opening really needed for the coax? I thought it was supposed to be more OB.

It's still all up in the air. My main thought/goal is to not have the coax mid (the tw section is a horn/sealed) boxed-in to minimize back pressure for the critical (imo) mid range. I gave up on OB for the woofers (agreed with comments here that two 10's just may not cut it (although the PureAudio Project dual 10's sounded nice), and hence going with a single 10 sealed w.

I've been a fan of OB cabs, i.e. Orange PPC212OB 2x12s, and with passive/active (and with my previous builds/measurements) I see & hear an advantages for mids.

I meant OB for the coax. Even having no back at all, your creating a resonate cavity, basically a U frame behind the coax. This will have some resonate peak to deal with. Definitely ditch the extra part above the woofer enclosure and damp the crap out of it.

Or actually vent it low enough that it either helps or is out of the pass band.

Or actually vent it low enough that it either helps or is out of the pass band...

Something certainly to consider for the coax.

A full open baffle vs vented vs tapered vent (which I did with a broad-ranger AudioNirvana 6.5 inch driver matched with a woofer) under consideration. I'd like to let the coax run, if it will with enough dBs, cleanly through ~380Hz with a slow roll below > so possibly a 1st order electrical HP at 190Hz (the mid has an fs of 75Hz) and bring the woofer in accordingly. I'll just have to see what the net HP roll (electrical combined with backwave) measures.

Edit: a real possibility having to go with a 2nd order HP, but easy enough as I use active btwn woofer and coax

I'm still at the drawing stage (weekend schedule is more focused on the snow while it lasts), and leaning back towards the naim dbl style, but possibly with a curved baffle providing a short-ish floor stander with top coax angled up a bit. Also going to change out back of coax open back (i.e. full open vs partial) and run impedance and frequency measurements per input provided- thx.

So, has anyone played with a dual chamber sealed woofer?

3 brads and a metal ruler > draws a nice curve. I’m thinking after cutting out by hand and sanding- I’ll probably use some 1/8th ply glued (and belt clamped) to the edge to smooth out my imperfections. I’ll then have a nice clean edge to use as a guide with a flush bit on a router to complete the sides.

Comments

Both have their place as the wood grain one is furniture where the black one is studio/road equipment in it looks/finish.

I like both.

and

I do like the contrast of the wood against a black grill, but to fit into our living room we need darker and/or a weathered grayish walnut look? I’ll be using baltic birch and will play around with finishes. Maybe like my previous build with a bit of gray stain tossed around? I’m also thinking maybe just a wood lower front (barn weathered look) and top, and sides and back black?

Oh, yeah!

Weathered barn/fence wood for the WIN!

So far thinking: top section (with ~open back coax offset) separate unit, providing a small bit of disconnect from bass unit (rubber footing).

Bass section one box, but with indent cut separating angled baffle from sq bottom ‘box’, as going with sealed bass vs double bass unit as per Naim DBL.

Top cap and front bottom sections weathered / stained, balance probably black stain with flat topcoat. Debating if base plate black or weathered stained, and if top plate and front bottom carries through the sides, or if terminated to sides (ie should sides go to front edge?).

Maybe get fancy with the wood on the side?

My last few builds have been darker walnut’ish stained sides with the balance black (front black cloth grill, with the top, bottom, and back black rolled duratex), which I tend to like, and works for my living room.

I’m leaning black (albeit a bit towards a pro stack look) with top cap and base a weathered gray/walnut. Not really going out on a limb here - but I’ve liked the look of the Vandies.

OK, now that I have use of a DELL I'm able to run impedance via DATS V3 (never used the system, it had been in the basement gathering dust, as not iMac friendly).

I've attached two pics; one for the Morel MW 1058 (open air, lifted off of table for venting). It looks like Re, Qes, Qts, and FS across-the-board are close to, but slightly higher than listed specs. Any comments, and how would a period of break-in affect these (if any)?

The other is for a Celestion 6in coax measured in its open-back 'box' with its passive crossover (3rd order HP on tweeter, the mid is run full without a filter). FYI I run this coax via an active HP ~360 to 380Hz, but for this sweep it is run full. Since in the past I've just run frequency sweeps for my Xover designs (and listening adjustments) what can you guys tell me about this? Thanks (DATS newbie).

I can tell you it's not an open back box. It's a vented box tuned to about 180Hz.

InDIYana Event Website

That’s what I was seeing - a bit surprised as here is a pick (w/o its bottom plate on). More of an opening than a port - so I thought.

I'm not surprised. That is just a large high tuned port.

InDIYana Event Website

This project may not ever get off the grid paper…

Since I have a nice stack of ⅛ Baltic Birch to laminate a curve, I’m going to toss in a curve somewhere (outside of baffle- mirrored, or at least the back). Here’s the latest (to be placed on low angled stands). Leaning all flat-black stained with ‘aged’ top and base walnut. But still scratching my head.

Nice, I also often use 1/4 inch graph paper. I think about form and function, and if a form could possibly serve a function. That would be the best. Not sure about the rear curve, but it could be beneficial. Not sure. Front curve is all about form. I like it best. Needs a function, diffraction maybe

I could proffer a couple of functional advantages, but primary goals are a) minimizing size appearance (per set volume for sealed 10in woofers), and b) to add a checkbox to trying something new (I did kerfing in last project, this one I'll be laminating 1/8in BB ply for a curved piece). I'm fine with my previous builds using 8 ½ in woofers, going to 10s size-wise for our living room is a bit of a stretch, but when I saw the Morel's... better to ask for forgiveness.

You could cut out an oval, or dare I say EGG shape, in the back piece.

I always appreciate feedback- but I’m not sure as to what you are recommending? As a back opening for the coax?

How to Cut Easy, DIY Elliptical Table Tops

Maybe I misinterpreted your drawing on the right side. I thought one option was to have a curved back.

I could use either of the top pics (your pic), ½ to form the back curve. Top right is ~ as I’m shooting for in my top right drawing. May take a look at ½ of your top left- i.e. deeper bottom section and narrower top - could work as well.

Thx

After measuring (DATS) vs co data, I sent the one woofer back for a replacement. Fs ( 39.64 Hz) looked a bit out from the company specs and from the other driver.

And here’s my latest configuration. I’ll target more of an open back / vent this time around and leaning towards a full black rubbed stain with flat (or semi) sealer. Tried a few samples for an aged top and base - not working for me.

Nice, full scale is best

I seem to end up with full scale drawings on grid and cardboard > helps me visualize the build, and often shows issues I’ll need to manage before I’ve created to much sawdust (and blown thru expensive Baltic birch).

Try leaving the top and bottom open? Just a thought...

The woofer will be sealed (with possibly a bit of eq), just wanting to not box in completely the mid / coax...but could run the front grill up and over the top?

Latest squibbles ~ 5 ½ in ‘frame’ black stained (semi gloss) with back duratex curved back enclosure set just inside. Creates vent for mid of coax (beyma 5 in) at top just under top cap.

Debating slight curved baffle. This would create a very difficult match to the back section - not sure if I can pull it off ? Probably best to stick with pure rectangular baffle.

Is the "vent" opening really needed for the coax? I thought it was supposed to be more OB.

It's still all up in the air. My main thought/goal is to not have the coax mid (the tw section is a horn/sealed) boxed-in to minimize back pressure for the critical (imo) mid range. I gave up on OB for the woofers (agreed with comments here that two 10's just may not cut it (although the PureAudio Project dual 10's sounded nice), and hence going with a single 10 sealed w.

I've been a fan of OB cabs, i.e. Orange PPC212OB 2x12s, and with passive/active (and with my previous builds/measurements) I see & hear an advantages for mids.

I meant OB for the coax. Even having no back at all, your creating a resonate cavity, basically a U frame behind the coax. This will have some resonate peak to deal with. Definitely ditch the extra part above the woofer enclosure and damp the crap out of it.

Or actually vent it low enough that it either helps or is out of the pass band.

Something certainly to consider for the coax.

A full open baffle vs vented vs tapered vent (which I did with a broad-ranger AudioNirvana 6.5 inch driver matched with a woofer) under consideration. I'd like to let the coax run, if it will with enough dBs, cleanly through ~380Hz with a slow roll below > so possibly a 1st order electrical HP at 190Hz (the mid has an fs of 75Hz) and bring the woofer in accordingly. I'll just have to see what the net HP roll (electrical combined with backwave) measures.

Edit: a real possibility having to go with a 2nd order HP, but easy enough as I use active btwn woofer and coax

I'm still at the drawing stage (weekend schedule is more focused on the snow while it lasts), and leaning back towards the naim dbl style, but possibly with a curved baffle providing a short-ish floor stander with top coax angled up a bit. Also going to change out back of coax open back (i.e. full open vs partial) and run impedance and frequency measurements per input provided- thx.

So, has anyone played with a dual chamber sealed woofer?

EDIT: I found this somewhat informative on the Dynaco A-35 spkr

https://archimago.blogspot.com/2023/02/retro-measure-dynaco-35-speakers-1972.html

3 brads and a metal ruler > draws a nice curve. I’m thinking after cutting out by hand and sanding- I’ll probably use some 1/8th ply glued (and belt clamped) to the edge to smooth out my imperfections. I’ll then have a nice clean edge to use as a guide with a flush bit on a router to complete the sides.