Site Links

Howdy, Stranger!

It looks like you're new here. If you want to get involved, click one of these buttons!

Quick Links

Categories

In this Discussion

Who's Online (0)

Looking for ideas to secure an MT cabinet to a bass bin

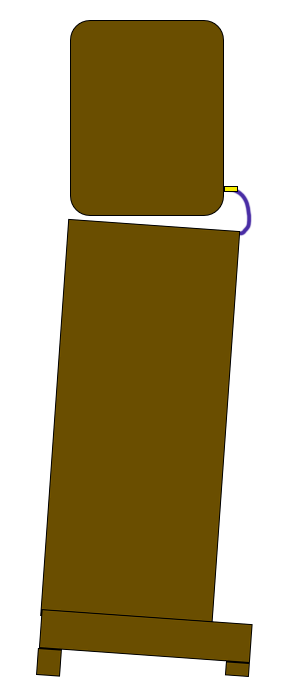

No doubt there are numerous ways to skin this cat, but I'm curious about what this board might come up with. This dilemma is similar to the how you might secure a bookshelf to a speaker stand, except in this case the bass bin is at a ~7° tilt (see rough sketch below). The top of the bass bin is flat and rectangular, 9" wide and about 13" deep. The MT is 7-1/2" wide at the baffle and tapers to about a 6" width at the back.

In the last iteration of this design I just used heavy duty speaker spikes (inverted), but would like to reach at least two of these three goals:

- Prevents the MT from toppling to the floor during dusting or an inadvertent bump.

- Keeps the MT planted in place horizontally and keeps it level, yet allows the MT to be moved or removed.

- Contributes to the design aesthetic visually, or is nearly invisible.

Whatcha got? Thanks for the input.

Comments

This won't secure it in place but will make it stay put better, isolates and provides the down angle (or close to it) . . .

https://www.amazon.com/Sound-Addicted-Isolation-Monitors-Acoustic/dp/B0757LTZJJ/ref=asc_df_B0757LTZJJ?hvadid=80745502742789&hvnetw=s&hvqmt=e&hvbmt=be&hvdev=c&hvlocint=&hvlocphy=&hvtargid=pla-4584345029882009

Hmm, I've got some extra 3/8" treadmill mat i could cut to use for isolation, depending where I end up with the mounting solution. Thanks.

In a previous build I drilled shallow indents (placed a bit of felt in the bottom- help with leveling) and used rubber feet on the base of my top box that fit into the indents.

I like the indent idea. Simple. And you could tune the tilt by how deep the hole is drilled for the feet to sink into.

Only other thing that popped in my head was to use speaker grill guides for a bit more positive retention. Most are plastic and would likely be busted off somewhat easily, but some have metal pins that friction fit into rubber cups:

https://amazon.com/Sound-Fastener-Speaker-Plastic-Button/dp/B08F59SFNS/ref=asc_df_B08F59SFNS/?hvadid=693402275727&hvpos=&hvnetw=g&hvrand=12658285258588308435&hvpone=&hvptwo=&hvqmt=&hvdev=c&hvdvcmdl=&hvlocint=&hvlocphy=9015624&hvtargid=pla-1384174993632&psc=1&mcid=0cd135a06eb53bf0bde800a0bc68da50&gad_source=1

I didn't drill too deep biz not much of an angle. And, only needed the front two (of the four) to keep 'er in place. Also, the back two rubber feet were easily sanded (on a belt sander) to level out.

Take a look at what Dan and Kerry used on the CSS Typhon speaker. It works extremely well, I saw it last fall at their place.

1.5" diameter Neo magnets?

InDIYana Event Website

Maybe use a French cleat in the front and a horizontal piece (part of the MT enclosure bottom) that extends in the back to pass a 1/4-20 bolt or thumbscrew through. You could stack washers or wooden discs under the rear piece to change the angle.

I'd use a black paint wedge smaller than the base of the MT with foam gasketed edges. Then use single machine bolt from the MT through the wedge into a single threaded insert on the top of the base bin.

This cleat and clamp idea is what I was migrating toward as I considered it today. The CSS "hinge" thingy is intriguing, But I don't foresee wanting or needing to alter the angle.

My latest thoughts are to add a couple of these JF outriggers I have on hand, possibly incorporating some ball and socket pegs. A cleat under the front of the MT would hold the heavier front end down. Still a work in progress that might evolve during assembly.

Top view would resemble this:

Well, as so often happens, I improvised at the end and didn't end up where i thought I would. I used an MDF block as a standoff, then fashioned a "T" on the bottom of the MT using 1/4" basswood. This is the bottom of the MT.

On the bass bin side I fabbed a bracket with grooves for the "T" to slide into, and cut it such that it levels the MT from the sloped top of the bass bin. This bracket is securely screwed to the top of the bass bin. I believe the friction fit of the "T" in the grooves with be all that is necessary to hold the MT in place. We'll see soon. The project will come together and be back in service this weekend.

Were these the speakers you brought to Dakota 2015? I found my notes from 2015 and I think these were called "The Relayers" and used RS28/W4-1320/8137 drivers. Or was that a different pair?

Yessir, those are the ones. WAF comes in two flavors (at least), aesthetically acceptable and practical from a daily living standpoint. These passed on the first count partly because of the sound, but not so much the second. My finishing skills will always be a work in progress, but the originals were a little tipsy and a drag with the dust cloth...

The new iteration with vinyl veneer, smooth black varnished trim and securely attached MT will be far more friendly to the duster. I'll let you guys decide whether the looks have improved, or not, in a day or two.

Precautions have been taken not to affect the sound. Hopefully there are no surprises there.

Those had outstanding bass.

Alright, I've heard enough to be confident that nothing bad happened in the transition. If anything, a couple aspects may be even better. Here is what has not been altered:

-Same baffles

-Same bass bin volume

-Same bass bin tuning

-Same relative angles of the baffles, to each other and to the floor

-Same drivers and crossover

These details have changed:

-The port is tapered inside and out instead of an abrupt hulk of PVC

-Each driver is 3-4" higher than before

-The MT volume is greater especially in depth

-And of course, aesthetics

The drivers are the Usher 8137A Kevlar/Carbon Fiber 7″ Woofer, in 35 liters tuned to ~41Hz. The mid is the Tang Band W4-1320SJ 4" Bamboo Cone Driver (Truncated frame) and the tweeter is the Dayton RS28F (Truncated frame). Only the TB is still available (barely).

Yep, still there. Saturday night I swear I could see the bass player play each note in my mind's eye. My experience may have been herbally enhanced, but WTH. The room is somewhat brighter than it was when the previous rendition existed. We've recently gone from carpet to LVP and area rugs in this space. It's a notable difference, but not in a bad way.

Those look great! Love the Ushers🤘🏼