Thats sweet Ron! I'll keep researching printers. I think an enclosed 3d printer would be good for us woodworkers with the dust and stuff floating around the air. I have 2 gravel bikes I need to sell before a purchase.

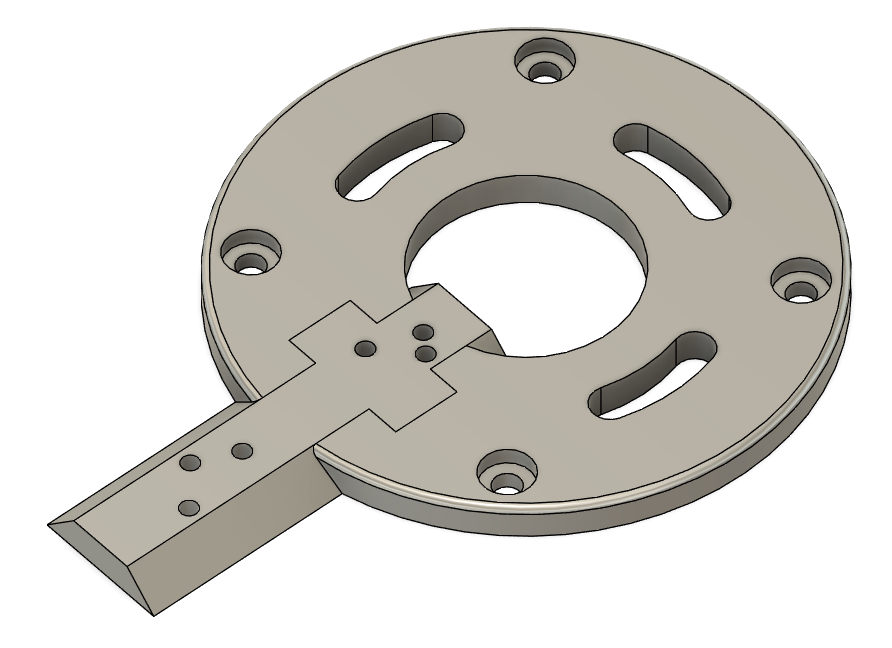

A couple nights ago I came up with an idea for making a 3D printed circle jig for my Dewalt DCW600B battery powered router. I came up with a parametric model which can take the OD of a couple drivers (tweeter and woofer) and the cutout diameters of each. Those parameters will generate a piece that fits into a base piece and accepts a 1/8" pin. Each driver's diameters will generate 3 holes -- 2 for the flush mounting cuts and 1 for the through-hole cut. The router bit's diameter is also able to be specified, and I even made a separate parameter for both the flush mount bit and through-hole bit.

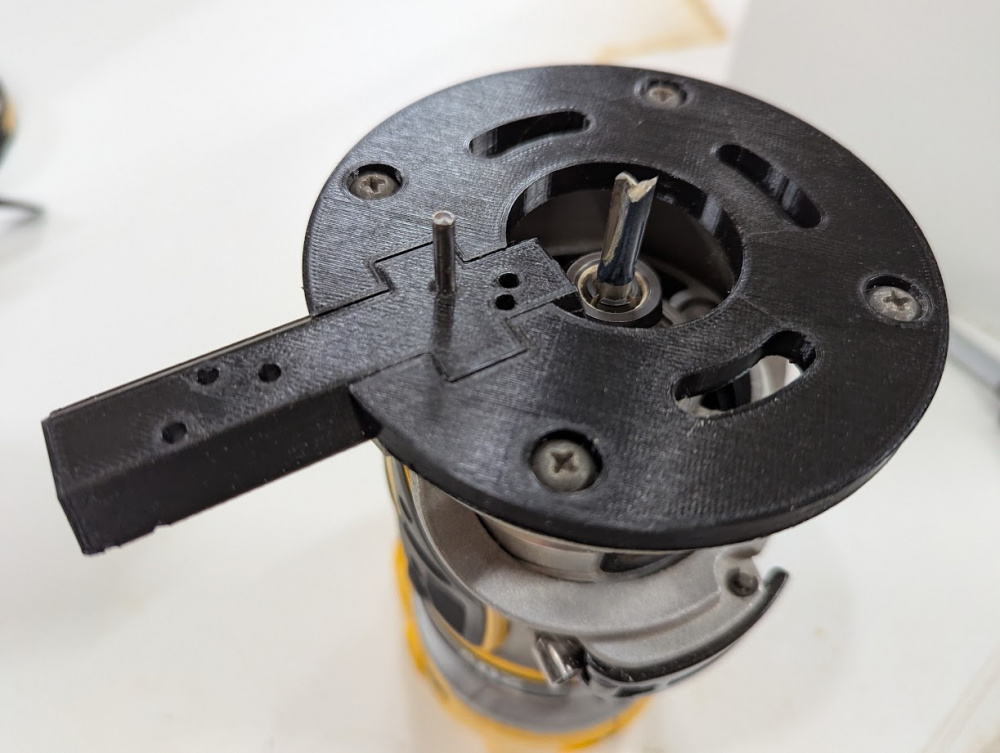

I haven't actually tested the cut yet (don't want to risk waking up my kid during naptime) but everything seems to fit really well, and the bit lined up right on the line I drew on my test baffle. I'm using this first on a speaker I'm developing with a Peerless XT25SC90-04 and a RS150P-4A, so all images below are for those drivers. Once I am happy with how it's working, I'd be happy to share the Fusion360 model with anyone, and could also generate driver-specific STL files pretty easily if anyone has requests.

The model with both the base plate and custom "arm":

The first print. Fit pretty well, but I'm reprinting the base with a slight roundover and fixing a small issue with the alignment of the mounting holes:

Inserted the pin, and the router bit lines up with the circle I drew:

Ya, I need to get a 3D printer and start printing up neat stuff like this. Also need to get a new Windows 11 laptop to replace my Windows 7 laptop. Most of these new fangled 3D printer software packages probably won't work under Windows 7.

@4thtry said:

Ya, I need to get a 3D printer and start printing up neat stuff like this. Also need to get a new Windows 11 laptop to replace my Windows 7 laptop. Most of these new fangled 3D printer software packages probably won't work under Windows 7.

@4thtry said:

Ya, I need to get a 3D printer and start printing up neat stuff like this. Also need to get a new Windows 11 laptop to replace my Windows 7 laptop. Most of these new fangled 3D printer software packages probably won't work under Windows 7.

What is your budget?

Minimum would be about 500 for a new laptop and another 500 for the 3D printer. But since I'll probably be dumping a minimum of 500 for a new laptop, I might as well go a little higher into the 700 to 1k range and get something a little nicer with a bigger screen and backlight type keyboard. Same thing goes for the 3D printer.

If you live by a microcenter they have alot of sales on Bambu labs printers right now, $219 for the A1 mini, 329 for A1 and I just picked up a P1S for $439 (member price). Probably wont use it for a week or two im trying to set stuff up in my basement and im pulling up the carpet first etc. Seems like if you want to print TPU the A1 mini and A1 are better buys, if your doing car stuff the P1S might be better. $219 for the mini is a great price (7"x7"x7") work area.

Been working on getting some area in my basement ready to add some heavy duty shelving. My basement was all boxes and stuff from when I moved. Been removing some old carpeting tiles, glue etc, trying to add lighting. taking longer than expected. Wanted to try and print something before the weekend ended. So I swapped the stock hot-end and extruder with the hardened steel versions 0.4mm. .

The good news is I ran a quick benchy and it printed fantastic! Really happy with the quality and speed. I used microcenter pla+ (was cheap with cardboard spool) I didn’t see any settings for that type of filament. I assume it printed with slightly off settings for regular PLA. The P1S is a bit harder to get your hands into to work on being enclosed.

Things I need to look into:

1) the app shows the machine disconnected when I was printing from the preloaded sliced files on the P1S. It seems to keep disconnecting but I was able to to run the cal from the app.

2) I only had 2 spools loaded. I preloaded / I selected slot 4 (green bambu filament) but after I started the benchy from the P1S. it just swapped back and printed from slot 1 (black) I assume because it was presliced with slot 1.

3) the screen suuuuucks to use. The tech at microcenter had an A1 and said he exclusively uses the app so I’ll have to figure out how to do everything from the Handy APP for iPhone. Maybe I should have got the A1. Is there another app you need other than “Handy” app?

Comments

Thats sweet Ron! I'll keep researching printers. I think an enclosed 3d printer would be good for us woodworkers with the dust and stuff floating around the air. I have 2 gravel bikes I need to sell before a purchase.

Just printed Turn table legs,

I built some feet inspired by Polk TSi300s.

A couple nights ago I came up with an idea for making a 3D printed circle jig for my Dewalt DCW600B battery powered router. I came up with a parametric model which can take the OD of a couple drivers (tweeter and woofer) and the cutout diameters of each. Those parameters will generate a piece that fits into a base piece and accepts a 1/8" pin. Each driver's diameters will generate 3 holes -- 2 for the flush mounting cuts and 1 for the through-hole cut. The router bit's diameter is also able to be specified, and I even made a separate parameter for both the flush mount bit and through-hole bit.

I haven't actually tested the cut yet (don't want to risk waking up my kid during naptime) but everything seems to fit really well, and the bit lined up right on the line I drew on my test baffle. I'm using this first on a speaker I'm developing with a Peerless XT25SC90-04 and a RS150P-4A, so all images below are for those drivers. Once I am happy with how it's working, I'd be happy to share the Fusion360 model with anyone, and could also generate driver-specific STL files pretty easily if anyone has requests.

The model with both the base plate and custom "arm":

The first print. Fit pretty well, but I'm reprinting the base with a slight roundover and fixing a small issue with the alignment of the mounting holes:

Inserted the pin, and the router bit lines up with the circle I drew:

Those look great! Sending you a PM.

I just printed up some port flares/mounting rings. This one is for 4" pvc. I put it on a street 90 for my current build.

@Timsie That router jig is awesome!! Definitely post that in the jigs thread too🤘🏼

I 2nd that ^ motion - very clever/creative use for that printer!

Ya, I need to get a 3D printer and start printing up neat stuff like this. Also need to get a new Windows 11 laptop to replace my Windows 7 laptop. Most of these new fangled 3D printer software packages probably won't work under Windows 7.

What is your budget?

Minimum would be about 500 for a new laptop and another 500 for the 3D printer. But since I'll probably be dumping a minimum of 500 for a new laptop, I might as well go a little higher into the 700 to 1k range and get something a little nicer with a bigger screen and backlight type keyboard. Same thing goes for the 3D printer.

You can get a lot of laptop for that money if you shop smart.

If you live by a microcenter they have alot of sales on Bambu labs printers right now, $219 for the A1 mini, 329 for A1 and I just picked up a P1S for $439 (member price). Probably wont use it for a week or two im trying to set stuff up in my basement and im pulling up the carpet first etc. Seems like if you want to print TPU the A1 mini and A1 are better buys, if your doing car stuff the P1S might be better. $219 for the mini is a great price (7"x7"x7") work area.

That thing looks as big as a jukebox! What are the approximate dimensions?

18 tall, 15.25 wide and 17-20 deep (20if you have a spool on the back. ) the AMS2 is 10” taller, it can go on top or on the side etc

Oh, that's not so bad. The perspective of the pic makes it look much larger.

Been working on getting some area in my basement ready to add some heavy duty shelving. My basement was all boxes and stuff from when I moved. Been removing some old carpeting tiles, glue etc, trying to add lighting. taking longer than expected. Wanted to try and print something before the weekend ended. So I swapped the stock hot-end and extruder with the hardened steel versions 0.4mm. .

The good news is I ran a quick benchy and it printed fantastic! Really happy with the quality and speed. I used microcenter pla+ (was cheap with cardboard spool) I didn’t see any settings for that type of filament. I assume it printed with slightly off settings for regular PLA. The P1S is a bit harder to get your hands into to work on being enclosed.

Things I need to look into:

1) the app shows the machine disconnected when I was printing from the preloaded sliced files on the P1S. It seems to keep disconnecting but I was able to to run the cal from the app.

2) I only had 2 spools loaded. I preloaded / I selected slot 4 (green bambu filament) but after I started the benchy from the P1S. it just swapped back and printed from slot 1 (black) I assume because it was presliced with slot 1.

3) the screen suuuuucks to use. The tech at microcenter had an A1 and said he exclusively uses the app so I’ll have to figure out how to do everything from the Handy APP for iPhone. Maybe I should have got the A1. Is there another app you need other than “Handy” app?