Site Links

Howdy, Stranger!

It looks like you're new here. If you want to get involved, click one of these buttons!

Quick Links

Categories

In this Discussion

Who's Online (0)

Noltik DaMe

I decided I wanted to do something with the old drivers I have and then decided I wanted a curved cabinet.

My first time making something not square so I went small.

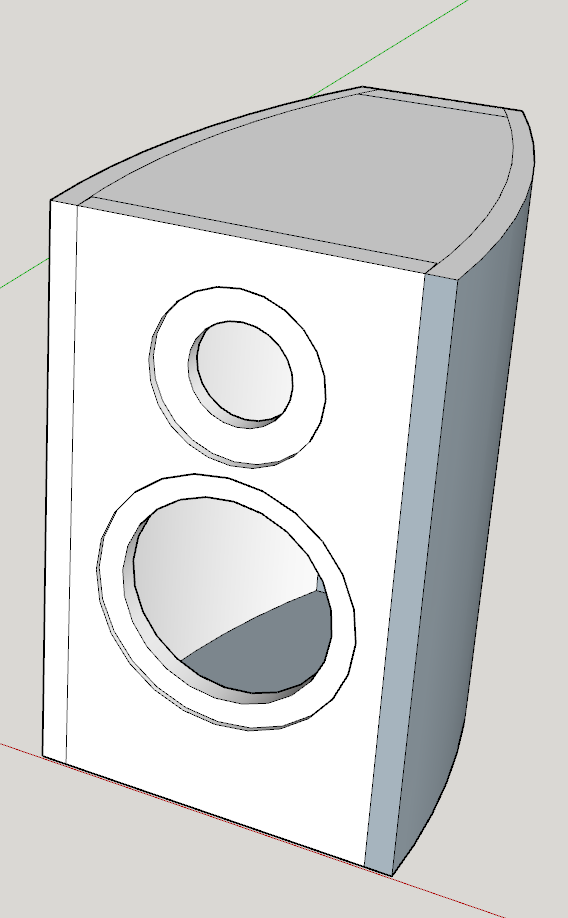

The DA115 seemed like a good option and got a MeloDavid twitter, after drawing a bit got to:

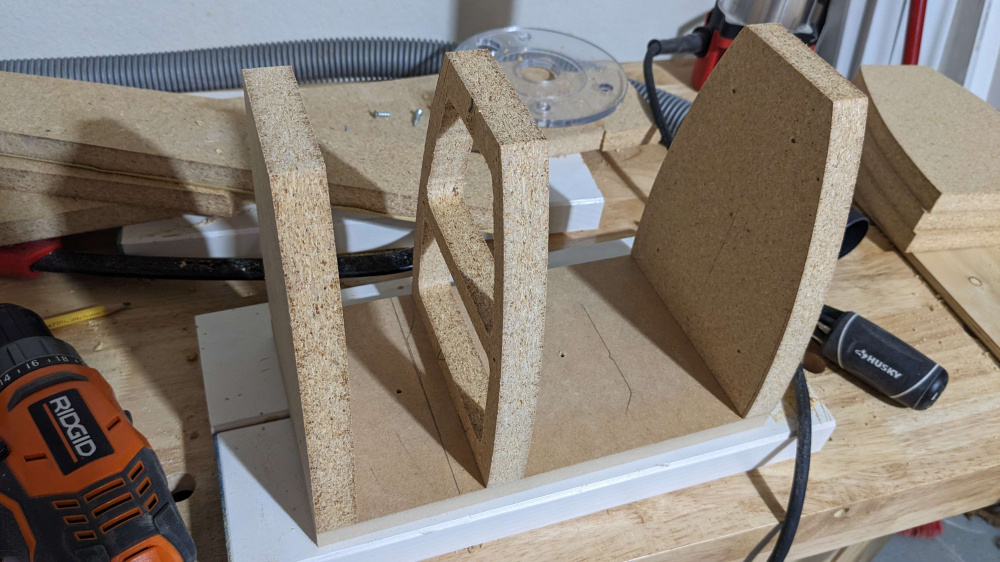

Was planning to use a CNC to cut the curved top, bottom and brace, but the makerspace had a water leak after a storm and the CNC was out of commission.

Printed the brace design and made a template out of plywood:

First attempt to glue the sides were a mess, so I had to make a jig:

1 layer on:

Had to hand cut the extra material as routing was not a stable operation:

The 2 layers and driver fit check:

Then build the pair:

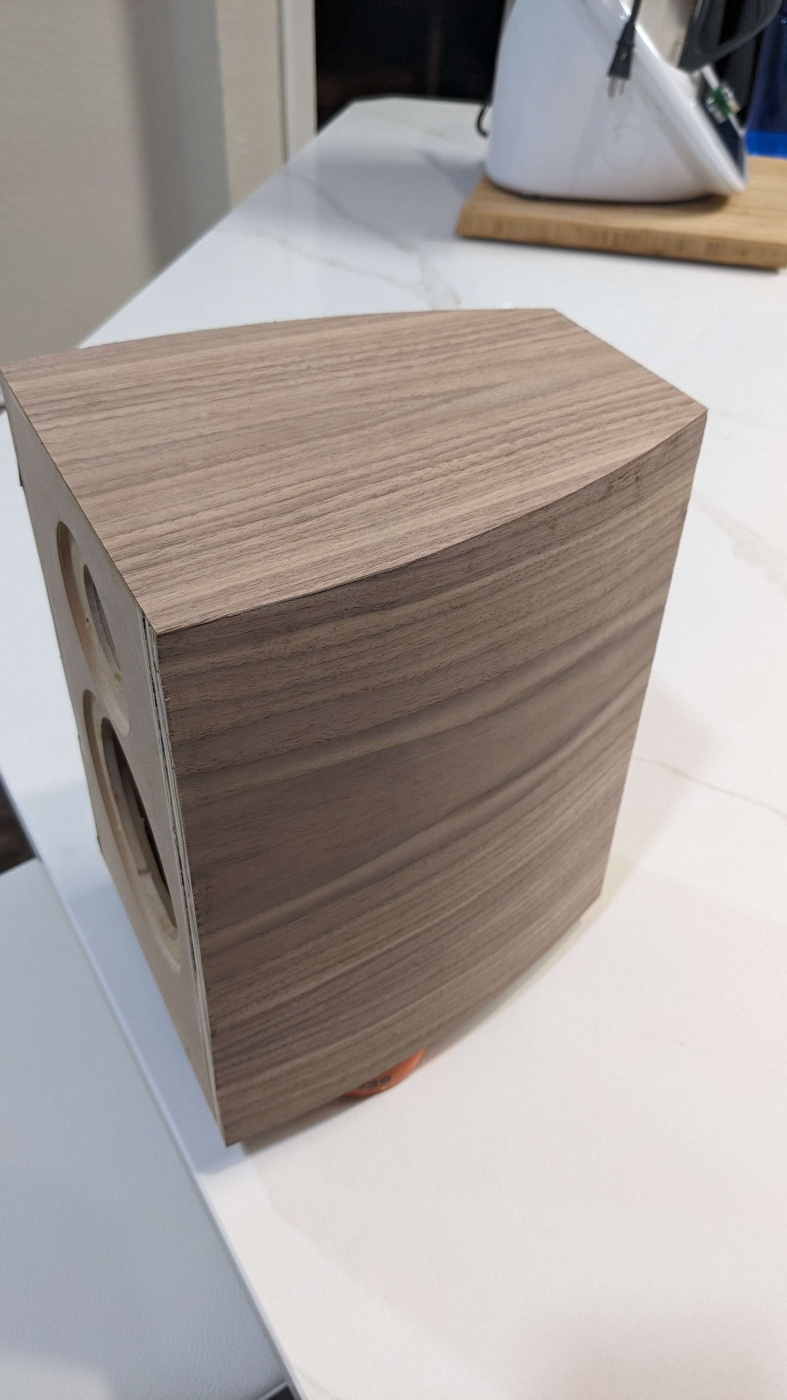

Decided to veneer and add a 1/2" roundover:

I printed the ports, went with 28mm diameter:

1 of the cabs has a void in the corner:

Filled with epoxy:

Will route it later.

Measuring and XO is ongoing.

Comments

The sides ended being 15mm thick, front and back are 12mm and the curved elements are 19mm.

looking great. How thick is the ply you are using on the sides? no issues bending? Is the front going to be painted?

The 1st layer was 6mm, second was 9mm. Once I used the jig, it bent with no problems.

I will paint the front and back, I guess black will be used.

It filled in nicely.

Right on! Divide and conquer👍🏻 Looking good.

How do you cut the back flat and flush?

A table saw fence can adapt with an extension to make it higher or clamp a right angle jig to run it through for flatness.

You could also block sand a lot.

You can mount a router to a block and set depth to block depth and use like a block plane.

InDIYana Event Website

With that hand saw and elbow grease.

Listening a bit.