Site Links

Howdy, Stranger!

It looks like you're new here. If you want to get involved, click one of these buttons!

Quick Links

Categories

In this Discussion

Who's Online (0)

Got a 3d printer. Made a Beasthorn

I just picked up a Bambu A1 a couple weeks ago. I always wanted to build a large circular horn speaker with the horn set on top of the speaker. I am not sure how it will sound, but should be a fun experiment. I thought i would try it first with the Beast mode tweeter since I have a pair. I plan to pair them with the dayton SD215A-88. The horn has an outer diameter of 10".

Comments

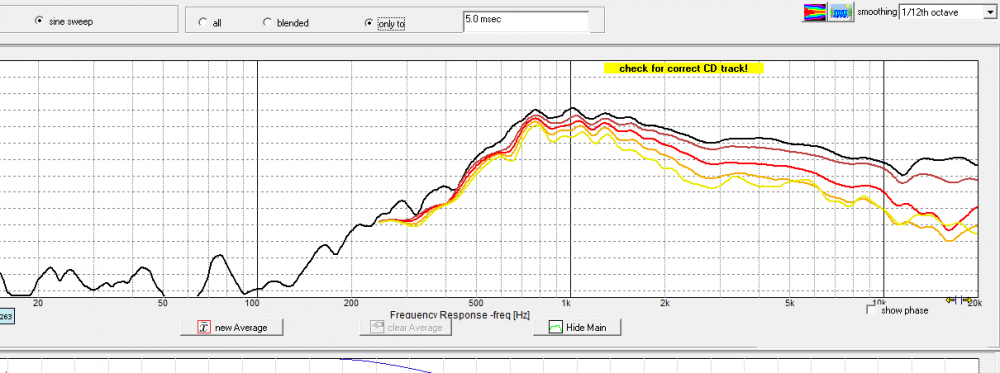

I took a few measurements of the driver from 0-60 degrees. I also put it in xsim and threw together a quick second order filter with an L-Pad. I think I could easily run this tweeter down to a 1khz crossover point.

Looks like you made full use of the bed size. I have the same printer. How long was the print? Infill and wall count?

It took almost 24 hours to print. I can't remember the wall size, but I did 15% infill.

I am going to print one tonight with at little shorter throat. I am hoping to smooth out the response a little more.

How did you design it? Ath4?

I just designed it in Solidworks with no horn design software. I need to take some time to learn it at some point. Right now I am just taking the brute force approach to see what I stumble upon. I have done that in the past with waveguides and had fairly good success. I am only out the cost of filament to give this a try.

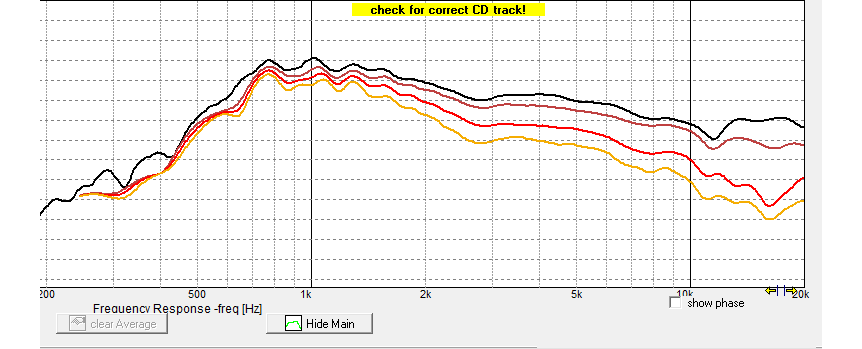

I made a couple more iterations. I made one with a shorter throat, but it had a larger dip around 10k. Then I went back to the original design but reduced the outer radius which made the inner part of the horn larger. This smoothed out the 3500 to 9k area.

Here is the shorter design.

The latest one is a 2 part design.

Here is the 0-60 degree set of sweeps.

Here is a comparison of the 1st design and the latest. The latest is in red.

Here is the short throat version versus the latest. Latest in red.

I did a quick crossover, and I think the latest version is something I can work with. Now I just need to start the box for the 8" woofer.

Kudos

You're doing great, but I think if you look at the off axis of the first horn, it's clearly the better guide. The dip at 12k ish on axis will be filled in by the off axis bump. Also notice that on the first one the off axis measurements spread in parallel for the most part where the second one not as much. I'm pretty sure the first horn will sound much more even.

I agree somewhat. The last horn was difficult to clamp to the table, and my measurements might not be as good. I couldn't easily rotate it. I should find a better clamping method and remeasure. I may have to build them both and see what they sound like.

I remeasured again tonight, and it looks better, but at 60 degrees it gets funky.

here is to 60

Looks good out to 45

Ugly_Woofer, you may be right. Maybe I should have made duplicates of the first iteration. I have now printed 2 of the 3rd, so I will start with that one, but may need to pivot back to the first if I don't like it.

I got some cabinets put together and mounted the horns on top. I will get some measurements soon.

Beautiful work thus far, looks like you used every bit of the print volume available on the A1!

I got the look I was going for, but now to see if I can get them to sound good.