Site Links

Howdy, Stranger!

It looks like you're new here. If you want to get involved, click one of these buttons!

Quick Links

Categories

In this Discussion

Who's Online (0)

The Figs; a compact bookshelf speaker with the SIG140, ND28F, ND140PR

After having finished my CR180 speaker, I had a friend come over and listen to them, and she then wanted me to build her a pair of speakers. Her use case was both for TV use, and music. Also wanted them to be small enough to fit on her entertainment center next to the TV. I had my subwoofer that was not being used; which was a nice size for her to integrate and use to supplement the low end.

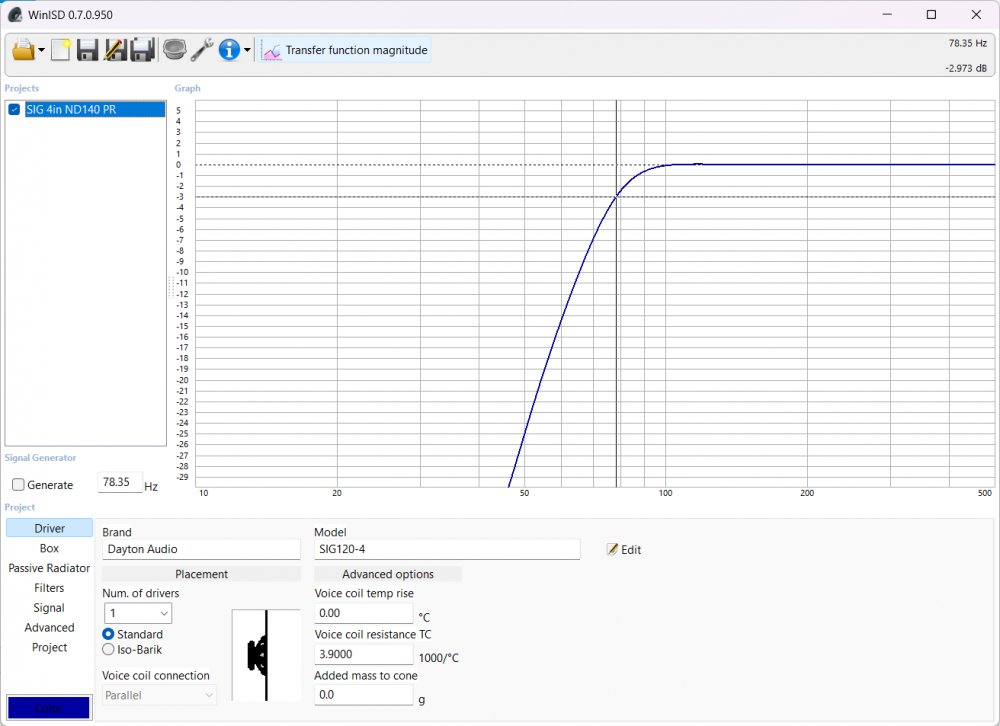

I had been curious about the newly released Dayton Audio Signature series; and found the 4in modeled very nicely. 3.5L enclosure, with the ND140 PR (much easier to fit than a port), 80hz tuning on the PR with no added weight, and a modeled F3 of 78hz. Perfect to mate to a subwoofer. Excursion of the woofer remains under xmax at 101dB and 30W of input power. PR isn't near it's xmax limits.

I choose the Dayton Audio 1 1/8" tweeter to give me a nice amount of overlap with the woofer when picking a crossover point. Small external diameter should make it easy to place close to the woofer.

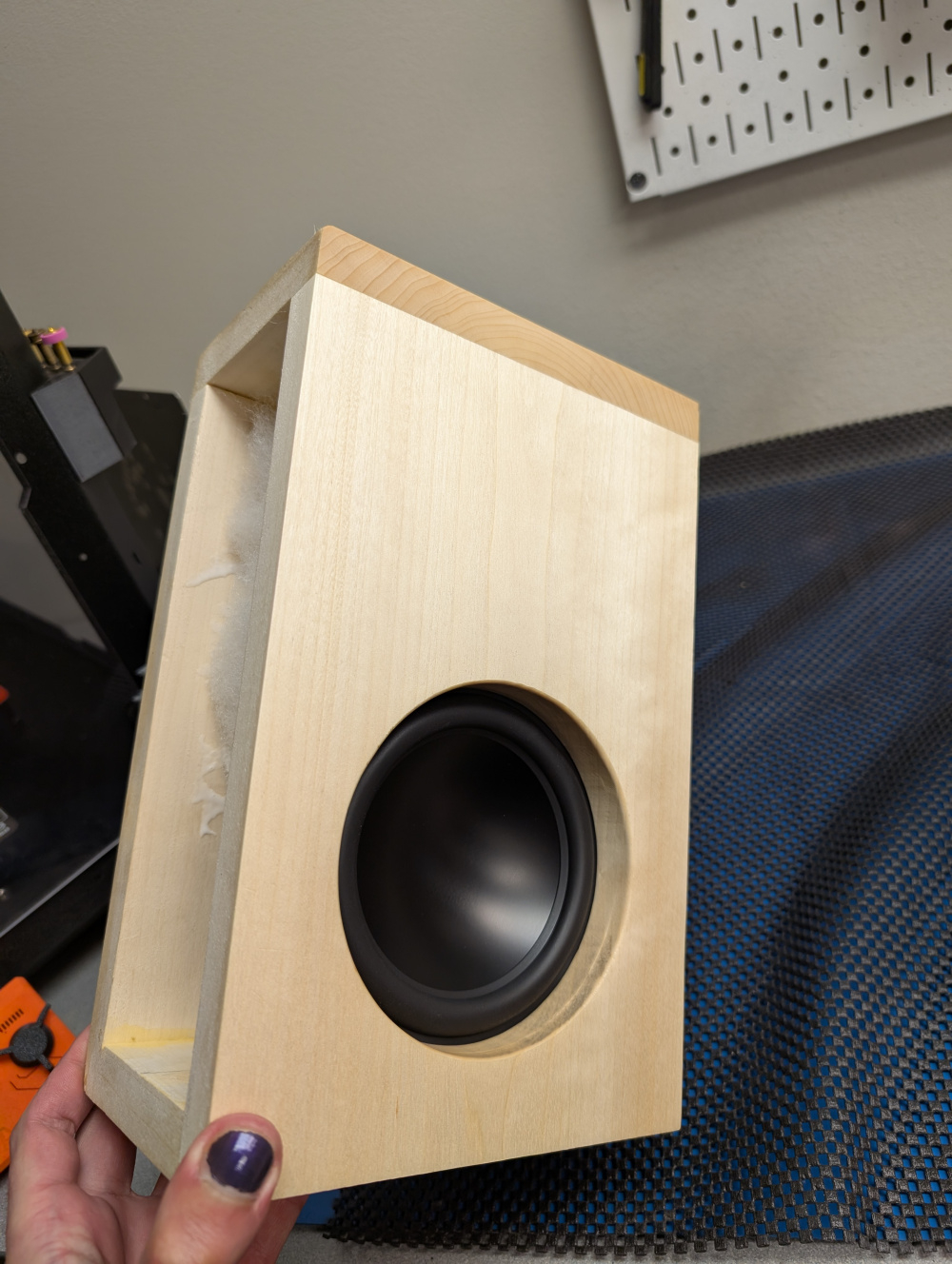

For the enclosure, I was enamored with purpleheart wood after using it to build a cutting board for my parents over Christmas. Rockler has a 3/4" x 5" x24" piece for only $25; chopped in half makes a perfect pair of front baffles with the woofer just barely fitting. All that was needed was to design the rest of the enclosure to net me 3.5L. Due to the fairly narrow baffle, I had to place the woofer near the top of the enclosure, and the PR at the bottom; otherwise the rear of the woofer and PR would interfere with each other. Overall size is 11in high, 5in width, and 7 7/8in deep. The baffle is slightly longer than the enclosure, giving it a slight 3 degree tilt upward. Attatched CAD design.

Comments

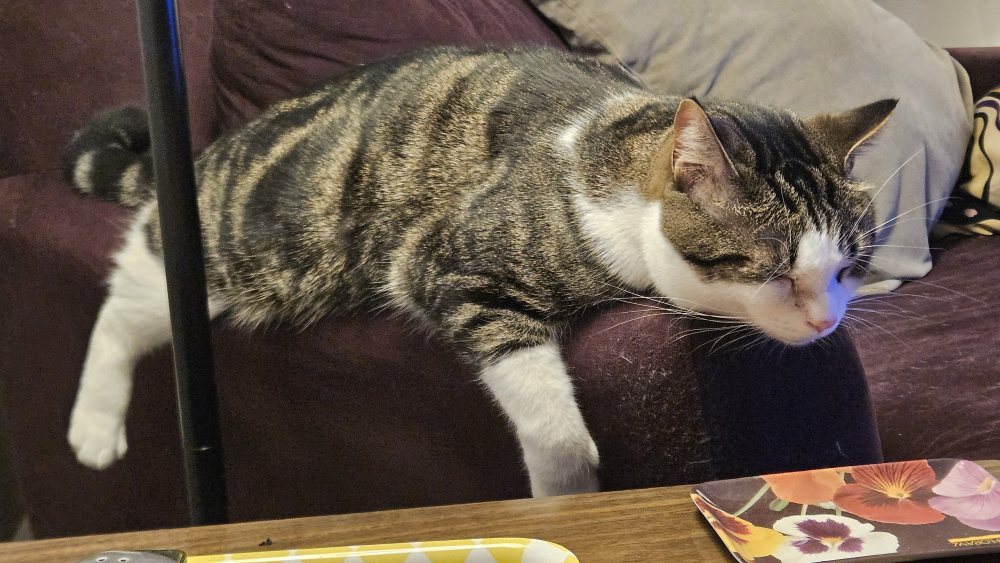

Ope, almost forgot. Name comes from my friends cat, Fig!

Had a purrball very similar until a couple months ago. Looked like the printer ran out of black ink with these neat kind of color or not patterns. We called her Precious because she knew how pretty she was.

Your build looks cool, keep it up!

InDIYana Event Website

Adorable! Look likes they could be siblings.

For the front baffle, being solid wood, I planned on adhering it using a very flexible construction adhesive (Sikabond). This will hopefully allow expansion and contraction of the front baffle without splitting.

After cutting the rest of the enclosure with 1/2in MDF, I remembered how dusty it is. And my cuts weren't the best or most square. Working with smaller pieces in a smaller room proved to be difficult. I had used some Aspen wood for a different project, and found it to be quite nice. Would pair will with the Purpleheart I thought...

So here comes the risky part. Making the entire enclosure with solid wood, and using two differing species. Figured worst comes to worst, they crack and split over time, and I just have to remake them.

Rear of the enclosure cut, assembled, and finished with Tried & True.

After assembly (and some mild wood filler on a few small gaps...) the enclosure was lined with some poly fill. The PR was slightly difficulty placed in the enclosure (rear mounted). A right angle ratcheting screwdriver helped.

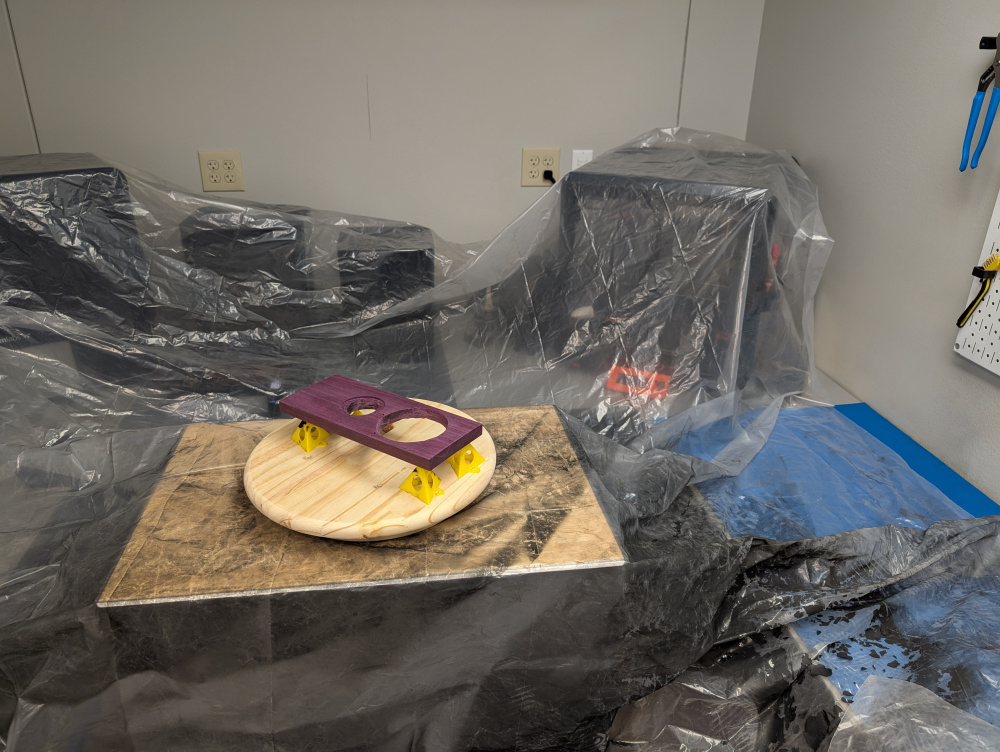

Ah the front baffle. Let me start by saying, purpleheart is an absolute pain in the a** to work with. It's very hard, and smells quite bad when routed/sanded. When routing out the driver holes, I managed to snap my new solid carbide router bit. Was fortunately not injured, and was able to finish with the straight bit that came with the circular jig. But, I persisted. Some mild damage, but all will be hidden by the woofer.

Realized after that the tweeter cutout was sliiiightly too small. A dremel with a sanding drum enlarged the holes, but also burned the wood slightly. But, will be covered by the tweeter. Baffles were sanded, and sun baked for a week to revitalize the purple color. Is quite pretty!

Last step was a top coat of Varathane Spar Urethane in Satin, for UV resistance. 3 coats, sanded with 320 grit before the final coat.

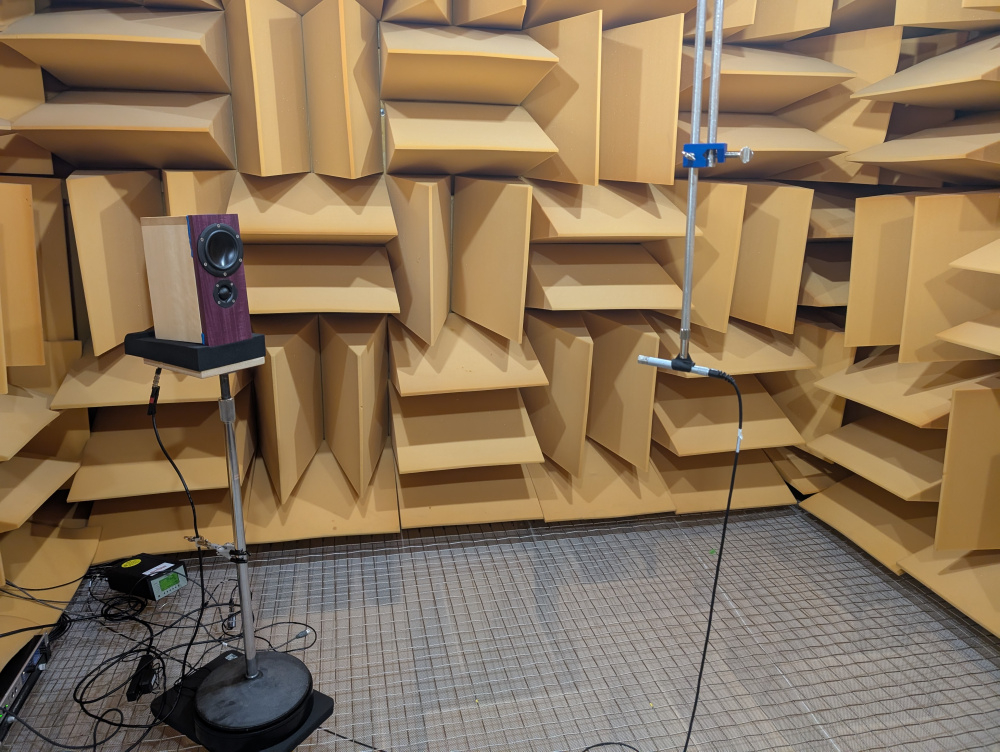

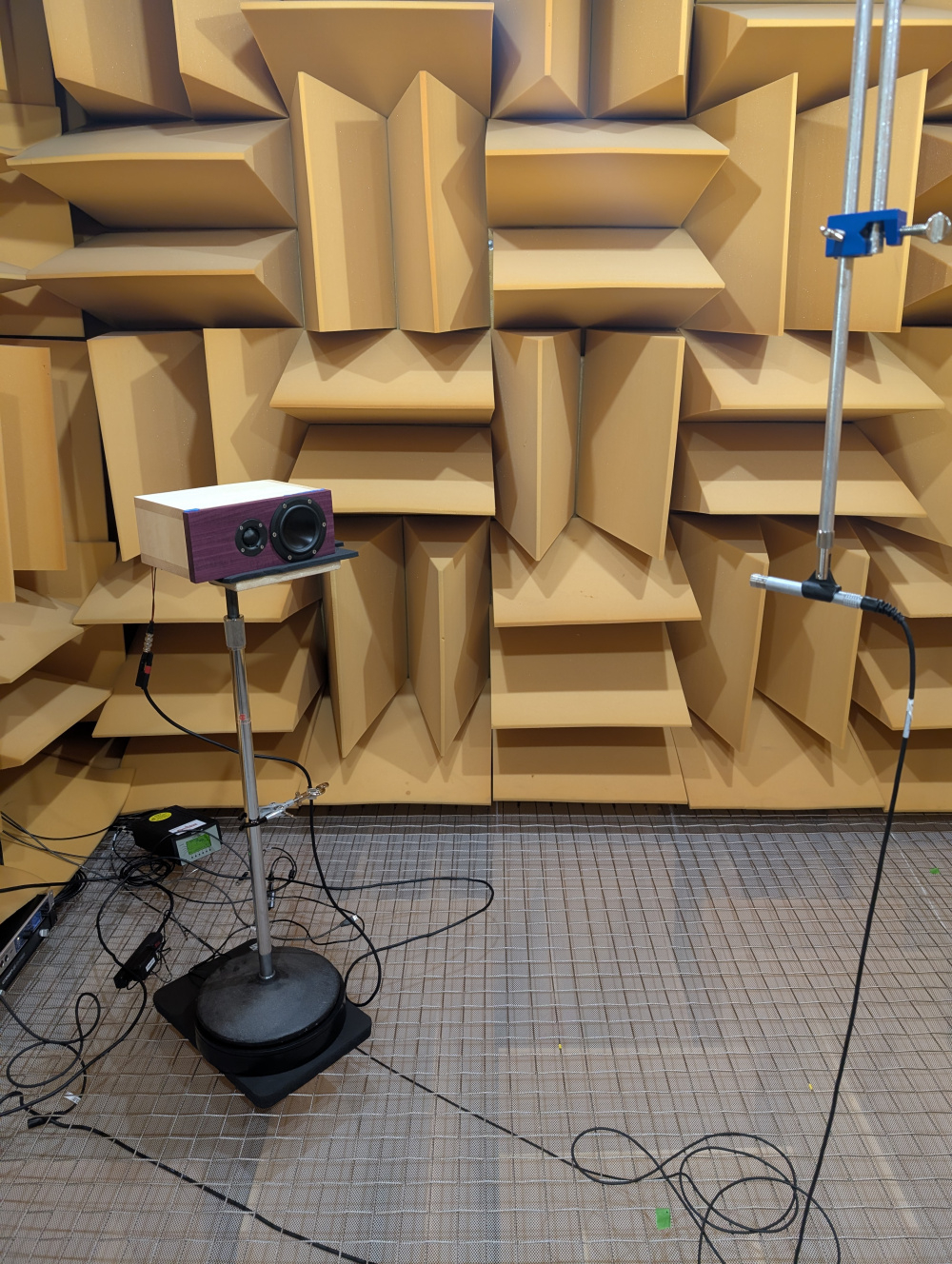

Speakers have been (temporarily) assembled! Using some alien tape to hold the baffle on and provide an air tight seal. Measurements should happen today or tomorrow. I have also kept the other speaker in our fabrication area; which is in a storage area of our building. Uninsulated, so it sees humidity and temperature swings. So far, no cracks or issues in the solid wood enclosure.

Some beauty pics in the mean time...

I realize this is a temporary state, but I hope you have a decent supply of these available. Nice work.

The drivers are properly attached; just the baffle is temporarily on. Reused some stainless steel screws I had around; so probably won't change to black ones. Partly because those stainless steel screws are a finer thread; easier to use on such hard wood.

It's been a while since I built a tube preamp chassis out of Purpleheart, but I still remember getting splinters from handling the rough cut wood.

Finally got the speakers measured. Full off axis measurements on both the tweeter and woofer; 360 degrees each.

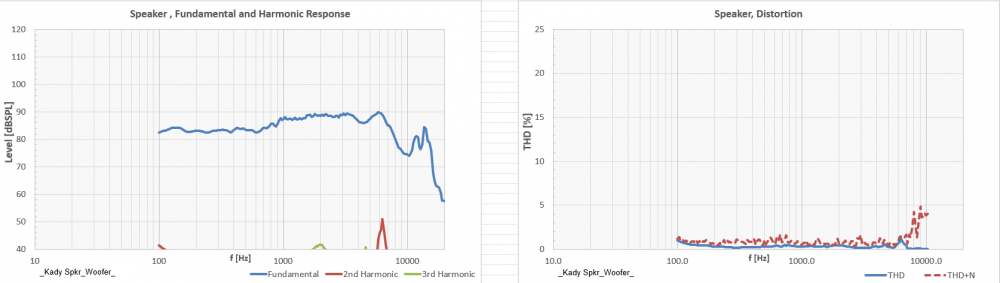

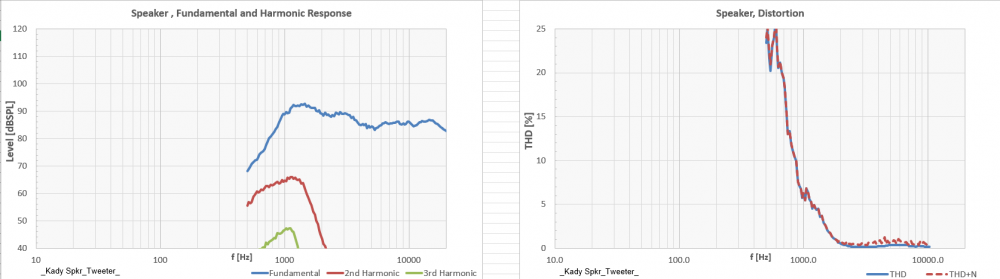

On axis measurements for each driver. Woofer was stopped at 100hz, and tweeter at 500hz. 2.83V each, 1m distance. Quite a smooth response from the woofer.

Next is to import all the data into VituixCAD and start modeling! Will undoubtedly be posting some crossover options here for options and suggestions.